License Free Software for IR Thermometers

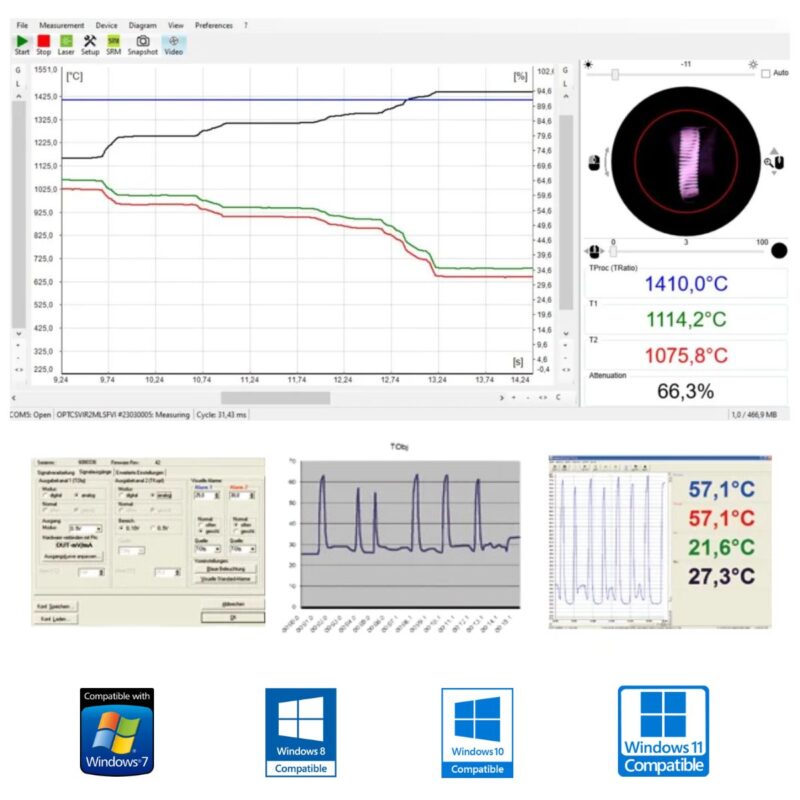

Optris Compact Connect is a user-friendly, license-free software designed for seamless integration with Optris’ fixed-installed infrared thermometers, particularly the CS, CSmicro, and CT series.

It facilitates swift and straightforward parameterization of these devices, while also providing robust tools for real-time temperature data analysis and documentation, thereby enhancing process control efficiency.

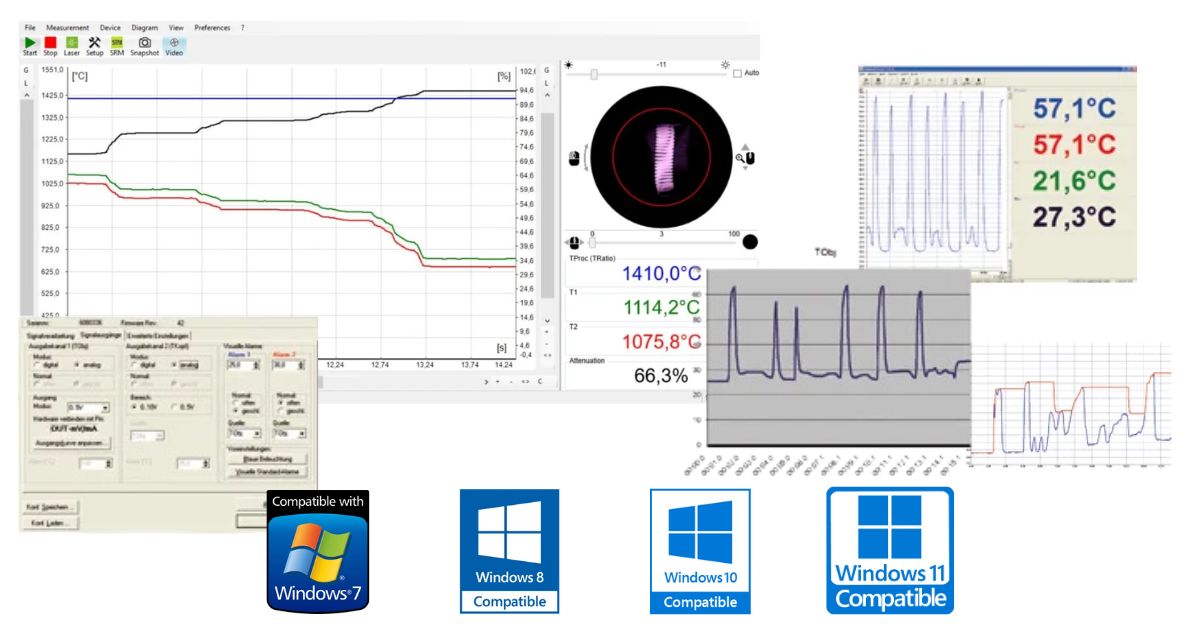

The software offers an intuitive interface that allows users to monitor data from multiple sensors simultaneously and export temperature information to Excel or MS Word for further analysis. For CT and CTlaser IR thermometers, the software can manage up to eight different emissivity values and corresponding alarm levels, enabling simultaneous monitoring of various processes and materials.

The Compact Connect software is compatible with Windows 7, 8 or 10.