Professional Temperature Calibration Equipment

Here at Process Parameters, we offer a professional calibration service using our laboratory measurement equipment. Our team of highly trained experts are able to ensure that your temperature-measuring devices are performing correctly and conform to all manufacturer standards.

Whatever industry you’re in, if you’re using temperature measuring equipment, then accuracy is critical. But when used over time, your equipment can lose accuracy, particularly as a result of extreme temperatures, humidity and general wear and tear. What’s more, if you’re working in a regulated environment, then the instruments you use may need to be periodically calibrated to ensure compliance with the relevant regulations.

Temperature calibration is the process of comparing a reading on one piece of equipment, with that on another piece of equipment that has been calibrated to a known set of parameters. Most temperature measurement equipment will need to be calibrated on an ongoing basis during its lifetime to ensure it continues to be accurate.

Regular calibration of temperature sensors and probes also provides users with peace of mind and confidence in the results produced, monitored, and recorded.

If you’d like a free quote, contact us now for a quotation.

Contact us for a calibration quote

Traceable thermometer & probe calibration equipment to ISO standards

We offer a traceable calibration service, and our calibration is carried out in accordance with our quality management accreditation ISO9001:2015.

This industry standard means all measurements are traceable back to National Standards. Traceable calibration is an appropriate calibration for most applications.

Our Thermometer Calibration expertise

As temperature measurement specialists with our unique industry expertise, our temperature calibration services ensure the highest level of accuracy of your equipment as well as compliance with regulatory guidelines.

Our Temperature Calibration Services

We offer a fast turnaround on temperature calibration services in our laboratory at our premises in Maidenhead, often within 3-4 days. Contact us with your requirements, we would be glad to help.

Contact us for help with calibrationSensor and Instrument Calibration

We offer calibration in respect of a number of different temperature measurement instruments including:

In many industries, even the slightest variance in the required temperature can adversely affect both the quality of a product and safety, particularly in the food and drink industry and in the production of certain materials. However, a number of operational conditions can affect the accuracy of probe measurements, for example, extremes of temperature, cycling temperature and knocks and damage. Regular calibration of temperature probes is, therefore, essential to ensure they remain accurate.

The recommended frequency of the calibration will vary depending on the amount and manner in which a probe is used, the industry you are operating in, and the operational conditions. We can calibrate temperature probes at temperatures between -30°C to +240 °C.

- We calibrate Thermocouples, RTDs, Thermistors and Temperature Transmitters.

- We can measure all thermocouple types.

- All RTD types including Pt100 and Pt1000. 2, 3 or 4 wire. All standard resistance coefficients.

- Process signals including 4-20mA and voltages.

See our page on calibration for PT100 sensors.

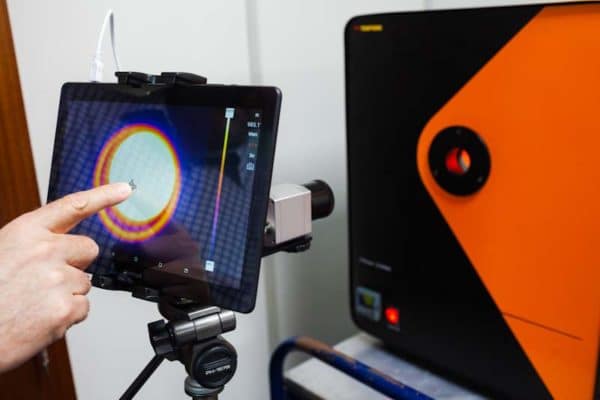

Infrared Thermal Imaging Cameras are factory calibrated to ensure precision and accuracy. However, like other equipment, over time, the electronic components age and the measurements they produce can start to drift. Other factors such as dust and dirt can also start to affect the equipment, but errors can be hard to detect. Therefore, an essential part of maintaining your infrared camera for both longevity and accuracy is ensuring it is periodically checked and recalibrated as necessary.

With particular expertise in the Optris range of infrared cameras, our infrared camera calibration can calibrate at temperatures of between 0 to 1200°C.

As an Optris Centre of Excellence, we have invested heavily in supporting the range of Optris Infrared Temperature Sensors that we offer. This not only includes our technical expertise with the product range but also enables us to calibrate many of the products in house with our own calibration facility.

- Black body temperature sources from ambient to 1200°C.

- Custom points – you choose the temperature we calibrate at.

- Independently calibrated reference pyrometers by German PTB.

- Optical geometry carefully controlled during calibration to ensure utmost precision.

- Support full range of outputs as required including mA, Voltage and thermocouple outputs. We can also support Optris USB interfaces and CompactConnect software directly.

- Calibrate other manufacturer’s infrared temperature sensors including Raytek, Land, Omega, Calex, DIAS and more.

Although most modern gauges are extremely robust, they can suffer from wear and tear and that in turn can affect their accuracy over time. Periodic gauge calibration verifies and, if needed, restores accuracy, and ensures consistent measurements.