Choosing an Infrared Pyrometer for Metals – 8 Important Things to Know

How to Choose an IR Camera for Liquid Metals

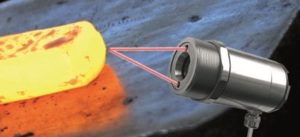

Infrared pyrometers are ideally suited to metals applications. As a non-contact method of measurement the sensor can be mounted at a safe distance from the often arduous environment of the process. There are however some careful considerations when selecting a sensor.

This guide will help you but remember, we are here to help with your sensor selection. Why not contact us now to discuss your application?

Which Thermometer Measures Metal?

Instruments called “pyrometers” are used to measure the temperature of metal objects. Pyrometers are specifically designed to measure high temperatures, which are common in metalworking processes such as metal casting, forging, and welding.

These devices work by detecting the thermal radiation (infrared radiation) emitted by the hot metal surface and converting it into a temperature reading.

Pyrometers are invaluable tools in industries where precise temperature control and monitoring of metal materials are essential for ensuring product quality and safety.

With a wavelength suitable for metal surfaces, the IR thermometers CTlaser 1M and 2M accurately measure metals of up to 2,200°C.

What to Know When Choosing an Infrared Pyrometer for Metals

1. Material

Knowing which material you wish to measure is extremely important to be able to take a reliable temperature measurement. This will have a direct impact on the sensor chosen and the emissivity setting you use. Remember that metallic parts are potentially tricky to measure but with careful sensor selection we can overcome these issues.

For metals we offer various sensors sensitive to short wavelength infrared radiation. Using the shortest wavelength possible for your measured temperature will help to avoid most issues associated with low, unknown or changing emissivity.

Of course, if your metallic material is coated, then it is the coating you are measuring, and this can sometimes make things easier.

2. Size of the Object to Measure

When using an infrared pyrometer, the size of the object being measured needs to be known so the correct sensor can be selected. The measuring spot for the sensor needs to be smaller than the part being measured and needs to be positioned completely on the part. We can offer plenty of choices when it comes to selecting a sensor with a variety of optical resolutions available including spot sizes down to less than 1mm in some cases.

For metals applications, we offer a variety of high-quality optics which give small measuring spots at a larger distance. These products use either laser aiming or through-the-lens video aiming.

Alternatively, the use of a Ratio Pyrometer will allow you to measure an object that is smaller than the measuring spot.

3. Ambient Temperature

Is the sensor you have chosen suitable for the operating environment it will be working in? If not, it is possible to cool or heat the sensor to ensure it meets the operating parameters. Often this is achieved by fitting air or water cooling.

Thermal shock is another phenomenon that can cause issues with infrared temperature measurement and needs to be avoided. This is a potential problem for smaller sensing heads and the addition of thermal mass, usually a larger housing, can overcome the issue.

4. Dust, Dirt, and Humidity

Is there a high possibility of debris or moisture settling on the lens of your sensor? Infrared temperature sensors work on their ability to be able to “see” the object you wish to measure. If there is dirt, debris, or condensation on the lens of the sensor the ability of the sensor to measure properly is diminished resulting in inaccurate measurements. It is possible to fit air purge collars to our sensors in order to prevent this.

In some metals applications, there is a potential for smoke, steam, and dust to be present in the environment and again this can prevent an accurate measurement from being taken. The Optris range of Ratio Pyrometers can cope with high levels of lens contamination and also blocking of the view by smoke, steam, and dust.

5. Aiming the Pyrometer

For many applications, it is easy to aim the sensor as the parts are large enough that it is almost impossible to miss. However, when considering smaller parts and when measuring through gaps in machinery aiming is extremely important.

Laser aiming is the simplest method and is commonly used. The Optris system of dual laser aiming shows you exactly where the sensor is aiming and also the size of the measuring spot.

Alternatively, through the lens video aiming systems are now available on our CSvideo and CTvideo products. This gives an extremely precise method of aiming the sensor even on red hot metals where lasers are sometimes not visible.

6. Measuring Through a Window?

It is quite normal in extreme environments to view through a protective window when using an infrared pyrometer. Protective windows protect the lens of the sensor from permanent damage and act as a sacrificial consumable in the most arduous of applications. You need to carefully consider the type of window being used.

You must ensure that the window transmits infrared energy in the part of the spectrum you need for your sensor. For example, if your sensor is sensitive to 1.6µm infrared energy, then your window should transmit this wavelength.

Once you have confirmed this you will also need to consider losses. Placing a window in front of your sensor is a bit like wearing sunglasses, some energy gets lost. Unfortunately, no material will transmit 100% of the energy. Thankfully, it is easy to compensate for these losses by entering a transmission value setting into your sensor’s software (very easy with Optris sensors). Usually, this transmission value is provided by the window manufacturer.

7. Pyrometer Output Signal

A sensor is no use if you cannot integrate it with your process measurement and control equipment. Of course, there are the industry standard mA and V signals, and these are utilised extensively across the Optris range. However, if you have been using a different type of sensor or intend to use a communication system, what can you do?

In some cases, Optris sensors are able to provide a thermocouple output so if you replace an existing thermocouple sensor, simply wire up your new IR sensor and no other configuration is required.

Many Optris sensors have the capability to fit an interface card which upgrades the capabilities of the sensor. This can be USB or Ethernet for communication with a PC, or ProfiBus or CANBus for industrial communication.

8. Speed of Response

By their very nature, infrared temperature sensors are massively quicker than contact probes such as thermocouples or RTDs. However, in some applications speed of response is extremely important. Typically, an Optris sensor will have a response time of less than 100 milliseconds but we offer products with response times as fast as 1 millisecond and with our new CT 4ML sensor the response time is now as low as 90µs.

Summary of Choosing an Infrared Pyrometer for Metals

This article is intended as a guide and does not replace our own free technical assistance which is always readily available.

At Process Parameters, we offer a range of pyrometers and thermal imaging cameras ideal for the metals industry. If you have any questions or would like help selecting the best pyrometer for your application, please get in touch and we’ll be happy to help.

Send An EnquiryFAQs

How do you check the temperature of hot metal?

To check the temperature of hot metal, use a pyrometer. Point the pyrometer’s sensor at the metal surface, and it will measure the thermal radiation emitted by the metal, providing an accurate temperature reading without physically touching the hot metal.

Can you use infrared thermometer on metal?

Related Articles:

- How Does a Thermal Imaging Camera Work?

- Benefits of Thermal Imaging Cameras

How Can a Thermal Imaging Camera Become Part of Your Process?

Can You Improve Your Thermal Efficiency With Imaging Cameras?