What is Emissivity? Why is it so Important?

What is Emissivity? Emissivity Meaning & Definition

What is emissivity? Emissivity is a measure of a material’s surface ability to emit infrared energy and forms a key part of being able to measure the temperature reliably with either an infrared temperature sensor or a thermal imaging camera.

The emissivity will depend on a number of factors such as the material itself, its surface finish, the temperature, the wavelength sensitivity of the sensor you are using, and sometimes on the measuring arrangement.

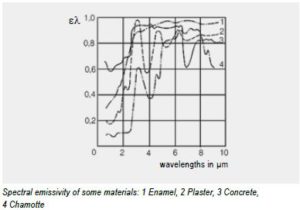

Many non-metallic objects tend to show a high and relatively constant emissivity regardless of surface finish, particularly when using a sensor sensitive to long-wavelength infrared.

Emissivity of Materials

Emissivity is a property of materials that describes their ability to emit thermal radiation. It is typically expressed as a value between 0 and 1, where 0 represents a perfectly reflective surface (no emission), and 1 represents a perfectly emissive surface (maximum emission).

Materials with high emissivity, close to 1, readily emit thermal radiation and are good at radiating heat. Materials like matte black paint, most metals, and rough surfaces tend to have high emissivity.

Materials with low emissivity, closer to 0, are poor emitters of thermal radiation. Smooth and shiny surfaces, such as polished metals and glass, often have low emissivity.

Emissivity is important in various applications, including temperature measurements with infrared thermometers and thermal imaging cameras, as it affects the accuracy of temperature readings from these devices. Matching the emissivity setting to the material being measured is crucial for accurate results.

Emissivity Chart

Here is a table of some common materials and their emissivity values in relation to wavelength.

For non-metallic parts, it is usually acceptable to use a long wavelength sensor such as a product from our ‘LT’ range of pyrometers, or a standard thermal imaging camera from the PI series. All operate in the 8-14µm which is at the long wavelength part of the infrared spectrum.

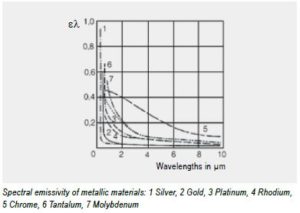

Metals tend to show a low emissivity and this is highly dependent on the surface finish of the material. Emissivity values also show a tendency to drop as the wavelength sensitivity of the sensor is increased. Here is a table showing the emissivity of various metals in relation to wavelength.

Due to the low and potentially variable emissivity generally found with metals, the shortest wavelength sensor should be used to ensure reliable measurements. The reason for this is that the emissivity value will generally be higher than for longer wavelengths and it will tend to be less variable.

The choice of the sensor will be governed to a degree by the measuring temperature range required. At very high temperatures a wavelength of 0.5 to 1.0µm should be used whilst sensors for lower temperatures are available with sensitivities to wavelengths of 1.6µm, 2.3µm and 3.9µm. Sensors in our range that meet these specifications are denoted by suffixes of 05M, 1M, 2M and 3M.

We also have a short wavelength thermal imaging camera, the PI 1M which is sensitive to 1.0µm wavelength infrared and will measure up to 1800°C.

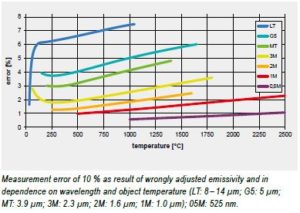

The following chart demonstrates the potential error when choosing a sensor. The lines are for different sensors with varying sensitivity to different wavelengths. It can be seen that for a 10% error in setting the emissivity correctly, the measuring error for an LT sensor with a wavelength of 8-14µm could be as much as 8%, however, for a 0.5µm or 1µm this error drops to as little as 1%.

In other words, the measurement becomes less dependent on the emissivity setting and can therefore cope with variations or errors, particularly with regard to high-temperature metals.

Selecting a Camera Based on Emissivity

You can therefore see that the emissivity value for your material is absolutely key to being able to take reliable temperature measurements using an infrared pyrometer.

When selecting a sensor or thermal imaging camera you should always check that the emissivity setting is adjustable, as it is on all Optris products, and you should carefully consider the wavelength of the sensor, particularly with regards to metals.

This article is intended as a guide and does not replace our own free technical assistance which is always readily available.

If you would like additional assistance, we can help you. Please contact us and we would be glad to discuss your application and help with your product selection.