Metals Applications – Miniature radiometric PI thermal imaging and High-Temperature Cameras with interchangeable lenses suitable for R&D, quality control and condition monitoring applications. Extensive ready-to-use package for a very attractive price which includes versatile image processing software and connection cables.

There are many methods of measuring the temperature of metals during processing, casting and forging. These have tended to be traditional contact thermocouples or non-contact pyrometers or infrared temperature sensors. These types of sensors have only been able to provide one measurement point at a time. Imagine having the ability to measure the temperature of your product or tooling across many thousands of measurement points and then use this data to directly control your process and quality. With Optris Thermal Imaging Cameras, this is now a reality.

see our metals Product guideOur High Temperature Camera products

Industrial Thermal Imaging Cameras

Industrial Thermal Imaging Cameras

Optris PI 08M Thermal Infrared Camera for Laser Applications

Industrial Thermal Imaging Cameras

Industrial Thermal Imaging Cameras

Optris PI 1M Thermal Imaging Camera for High Temperature Metals

Our range of high temperature thermal imaging cameras

High Temperature Infrared Camera For Metals

It does not matter what your application is, the Optris PI 1M and PI 05M have the ability to provide the data you need. With measuring ranges starting from 450°C and rising to 2000°C it is possible to cover applications including heat treatment, forging, casting, welding, laser sintering, additive manufacturing, wire drawing, stamping, induction heating and many more.

Rather than having just one measurement, it is now possible to monitor the temperature profile of a part or tool to ensure that this meets your needs. Require uniformity? Now you can see it. Require a temperature gradient? Easy.

A built-in Process Interface in each camera allows you to communicate directly with our existing process control equipment and will provide analogue outputs of temperature or direct alarm outputs. You can also control the camera remotely using the analogue and digital inputs.

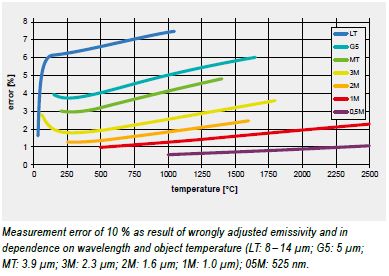

The short wavelengths that these cameras operate at make them ideal for high temperature and molten metals where the emissivity is extremely low or changing. The emissivity of metals at short wavelengths tend to be higher and the effects of an incorrect setting are greatly reduced.

High speed, high resolution thermal imagery are two other areas where Optris cameras excel. Both the PI 1M and PI 05M have resolutions of up to 764 x 480 pixels, allowing pixel sizes down to 90 μm allowing the measurement of the smallest objects.

Frame rates vary from 32 frames per second at full frame resolution, increasing to 1kHz for sub-frame modes. The camera can also output an analogue signal at 1kHz to your control equipment.

For applications where the part is not completely visible by the camera, or is a continuous process, a Line Scanning mode is built into the software system which is extremely easy to configure. Line scanners have traditionally been extremely expensive products but now high resolution, high-speed line scanning is available at a much lower cost.

Supporting the cameras is a complete range of high-quality accessories including cooling protection housings allowing use in ambient temperatures of up to 315°C. Air purging is built to ensure the lens is always free from dust and dirt.