Monitoring Lithium Ion Battery Charging in Automotive Applications

Case Study: How Do You Detect Thermal Runaway?

Client

Our client is a leading fire detection and alarm company, and their end customer is a well known manufacturer of medium and heavy duty trucks. The end customer was in the process of developing new electric vehicles and Process Parameters were engaged to monitor the temperature of their Lithium-ion batteries when charging.

The higher energy densities of Lithium-ion batteries allow for smaller battery size whilst retaining the same capacity. As a result, they are now an essential part of the transition from petrol and diesel to electric vehicles and vital to sustainable product development for vehicle manufacturers.

The Challenge: Thermal Runaway for Electric Vehicles

As part of both their product development and insurance compliance, the end customer needed to monitor the temperature of batteries when charging. It perhaps goes without saying that a battery that overheats when charging represents a significant fire and safety risk and therefore this was a pivotal part of their product development.

However, Li-ion batteries as used in electric vehicles can suffer from a phenomenon called Thermal Runaway. There are a variety of causes, but the effect is the same, a fire which is almost impossible to extinguish and generates poisonous smoke and fumes. Damage to surrounding property and structures can be severe. A temperature of just 70°C is all that is necessary to begin the Thermal Runaway process.

In the event of Thermal Runaway, normal fire detection methods do not provide sufficient protection. This is because normal fire and smoke sensors only detect the problem when it’s too late and by the time there is any smoke, the fire is usually well established and probably beyond control.

Measuring the surface temperature of the battery pack is a proven method of detecting localised heating and therefore faults that may cause a fire. But this project included some additional technical challenges, namely that any system we used needed to be integrated with the end customer’s site fire alarm. We also had to design a system that allowed us to actually see and access the batteries themselves.

Finally, there were some project management challenges involved as we were not working directly with the end client but via an intermediary. There was also a high degree of confidentially required as the project was still in the embargoed R&D phase. This necessitated collaborating with a number of different stakeholders throughout the lifespan of the project.

Solution To Thermal Monitoring and Runaway

Process Parameters were chosen for the project for a number of reasons which included our experience and understanding of the unique requirements and specific problems associated with Lithium Ion batteries. Apart from our technical ability, we were also chosen for our willingness and ability to collaborate and work alongside our client for the benefit of all parties.

So, how do you detect thermal runaway? And what did we do?

We chose to use four Optris Xi400 thermal imaging cameras mounted in protection housings, with two mounted on crane gantries and two mounted on portable trollies. We also used USB to Ethernet converters so that we could network to a PC some distance from the camera location.

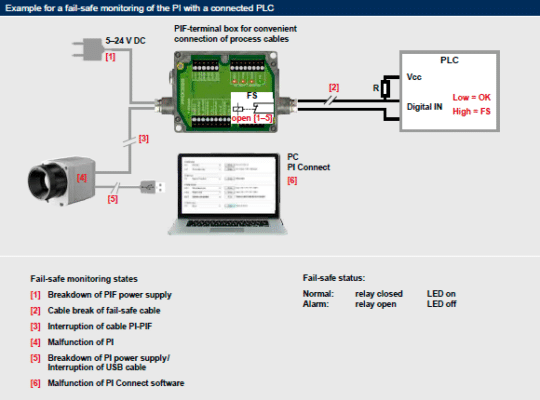

We then used Industrial Process Interfaces which allowed us to successfully integrate with the end customer’s fire alarm system, by using the alarm output feature to trigger the fire alarm system. Full support was provided on-site by Process Parameters and we were involved in both the commissioning of the system and training to those on site.

Outcome

The solution we chose proved to be a high quality and cost-effective solution that was easy to integrate. The system worked correctly out of the box and to date we have not received any service requests or fault issues.

With the development of electric vehicles, this is an area which is likely to become increasingly important to the end customer and there is an intention to use more cameras within their production environment when the trucks are launched to market. We therefore also ensured that the system was expandable and adaptable in order to cope with any future expansion and changes in requirement.

Finally, of course, we ensured that the end customer was able to meet the requirements of their insurance demands, without which they would have been prevented from charging the vehicles indoors which in turn would have had significant consequences in respect of this development project.

Need a Thermal Imaging Monitor?

Need an automotive thermal imager? Process Parameters Ltd is a UK based manufacturer of Industrial Temperature Sensors. We have a wealth of experience particularly in respect of Lithium-ion batteries and we manufacture all of our products to suit our customers designs.

Our solutions are backed by the highest levels of service and technical support. We’d be happy to discuss your application.

This article is intended as a guide and does not replace our own free technical assistance which is always readily available.

If you would like additional assistance, we can help you. Please contact us and we would be glad to discuss your application and help with your product selection.

T: 01628 778688

E: sales@processparameters.co.uk