Optris Xi 400 Spot Finder IR Compact Camera

£1,772.25

The newly developed Optris Xi 400 Spot Finder IR Camera impressively combines the benefits of thermal imaging cameras and infrared thermometers.

Technical Details

- Industrial imager with 382 x 288 pixels for exact temperature measurement of -20 °C to 900 °C (-4 °F to 1652 °F)

- Small sized rugged camera and motorized focus

- Optics FOV: 18° x 14° (f = 20), 29° x 22° (f = 12.7), 53° x 38° (f = 7.7), 80° x 54° (f = 5.7)

- Frame Rate of 80 Hz for monitoring fast thermal processes

- Superb distance-to-spot-size ratio up to 390:1 with sighting capabilities

- Cable Length: 1 m (standard), 3 m, 5 m, 10 m, 20 m

- Stainless steel housing

- Extensive ready-to-use package including versatile image processing software with line-scan feature and connection cables

Optris Xi 400 Compact Industrial Infrared Thermal Camera

The newly developed Optris Xi400 thermal imaging camera combines the benefits of a robust, compact pyrometer and an advanced infrared camera for the first time giving you more information and control about your process than any other temperature sensor. Process optimisation is made easier leading to production cost savings.

The Optris Xi 400 has a video recording frame of 80 Hz which allows for the monitoring and control of high-speed thermal processes. It even includes a line-scanning function for continuous processes such as paper, films or carpets.

The compact infrared thermal camera covers the temperature range of -20 °C to 900 °C and comes with a choice of optics including the new 80° lens for wide target areas. There is also a handy motorised focus to ensure that no matter where the camera is fixed, a pin-sharp image can be achieved with ease.

In addition to the standard USB plug-and-play functionality, this industrial imager can optionally use GigE Ethernet communication. A process interface provides a further three analogue outputs, two analogue inputs and a digital input to aid integration with PLCs, controllers and data loggers.

This 382 x 288 pixels combined IR sensor and camera is so compact it can easily fit into the palm of your hand and comes with a mounting nut and bracket.

Compact design and affordable pricing make the Optris Xi spot finder IR camera ideally suited for OEM applications and spot temperature sensor replacements.

What’s In The Box

- Process imager Xi 400

- USB cable (1 m (standard), 3 m, 5 m, 10 m, or 20 m)

- Mounting nut and bracket

- Standard PIF cable (1 m) incl. terminal block

- Optris PIX Connect software

Optris Xi 400 Additional Information & Software

The Xi 400 is also supplied with the new free Optris PIX Connect software, which has the same features as the former PI Connect, along with some new which make integration with your system extremely simple.

The infrared cameras and pyrometers from Optris can now also be operated easily using a smartphone or tablet using the IRmobile App for Android in the Google Play Store.

Calibration and a range of accessories are also available to purchase, such as a cooling jacket or interchangeable lenses for all of our Optris infrared sensors and thermal imaging camera purchases.

Areas of Application

The integrated spot finder function identifies the hottest (or coldest) spot in the image and automatically communicates these measurements without an external PC.

The Xi 400 Industrial Imager is versatile and perfectly suited for a multitude of measuring tasks, e.g. mechanical engineering or multi-sensor applications. The autonomous operation brings thermal imaging to a much wider range of applications and the Xi series will be attractive to machine builders and end users alike.

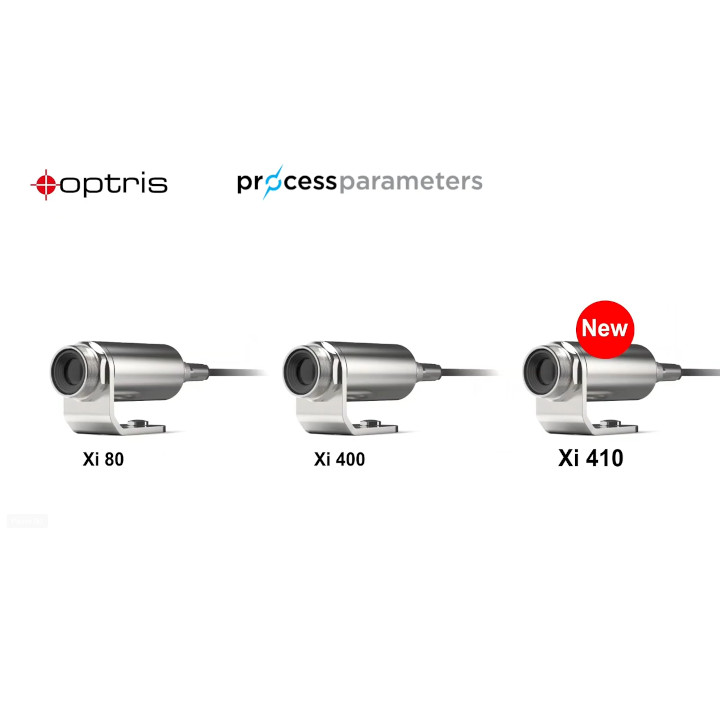

If you require a lower cost, lower resolution (80 x 80 pixels) take a look at the Xi 80. or the Xi 400 CM for applications which require outdoor housing.

Need some help? We supply a range of IR cameras for a range of applications. Contact us today for a detailed quotation for your requirements.

Email us at sales@processparameters.co.uk, or call 01628 778788.

| Cable Length | |

|---|---|

| PC Connectivity | |

| Frame Rate | |

| Optical Resolution | 382 x 288 pixels |

| Measuring Range | |

| Housing Material | |

| Brand | |

| Field of View |

What is The Optris Xi Series?

The Optris Xi series are miniature stainless steel-bodied cameras ideal for mounting into almost any machine environment. They are designed for permanent installation in order to provide condition monitoring and quality control temperature measurement. In the simplest form, they can monitor equipment for faults and provide an alarm in the case of an over temperature. The array of pixels allows temperature measurement of production machines as never before. Rather than basing quality control decisions on just one measurement, it is now possible to use many thousands of data points for this process. Built-in process interfaces allow easy system integration, providing either alarm outputs or industry-standard 4-20mA signals to your process control equipment. Connection via USB or Ethernet is provided and in the case of the Xi80, fully autonomous operation without the use of a PC is possible.What is an IR Camera?

An IR camera, also known as an infrared camera or thermal camera, is a device that captures and displays images based on the infrared radiation emitted by objects rather than visible light. Unlike traditional cameras, which rely on capturing visible light, an IR camera detects and records the heat energy emitted by objects and converts it into a visual representation of temperature variations. IR cameras utilise specialised sensors that can detect infrared radiation in different wavelengths. These sensors convert the detected infrared radiation into electrical signals, which are then processed to generate an image that represents the distribution of heat and temperature differences in the scene. The resulting images, called thermograms or thermal images, provide valuable insights into temperature patterns and anomalies that are not visible to the naked eye. IR cameras are widely used in various industries and applications, including electrical inspections, building diagnostics, predictive maintenance, medical imaging, firefighting, and security surveillance. By capturing and analysing thermal information, IR cameras can help identify heat leaks, insulation deficiencies, electrical problems, mechanical failures, and even hidden objects in low-visibility conditions. They play a crucial role in improving efficiency, safety, and decision-making in numerous fields and industrial applications where temperature-related data is essential.Related products

Industrial Thermal Imaging Cameras

Optris PI 450i CM Infrared IR Camera For Harsh Outdoor Conditions

Industrial Thermal Imaging Cameras

Optris Xi 400 CM Thermal Camera in Outdoor Housing for Condition Monitoring

Industrial Thermal Imaging Cameras

Industrial Thermal Imaging Cameras

Industrial Thermal Imaging Cameras

Optris PI450 G7 VGA Thermal Imaging Camera for Glass Applications