Browse our selection of platinum resistance thermometers, RTD sensor products, and categories for various applications and industries. Our Pt100 sensors are available in a wide temperature range.

Platinum Resistance Thermometers: Custom Pt100 Sensors

Platinum resistance thermometers (PRTs) offer exceptional accuracy and stability over a wide temperature range, making them ideal for demanding applications across various industries.

Key Benefits of Platinum Resistance Temperature Sensors

- Unparalleled Accuracy: Achieve precise temperature measurements with minimal error.

- Wide Temperature Range: Measure temperatures from -200°C to +850°C.

- Excellent Stability: Maintain consistent performance over time, even in harsh environments.

- High Repeatability: Ensure reliable and reproducible results.

- Versatility: Suitable for a wide range of applications, including industrial process control, laboratory research, and environmental monitoring.

Our Platinum RTD Sensor Range

- Pt100 Sensors: The most common type, offering a resistance of 100 ohms at 0°C.

- Pt1000 Sensors: Ideal for applications requiring higher resistance values.

- Two-Wire, Three-Wire, and Four-Wire Configurations: Choose the best option for your specific wiring requirements.

- Customisable Designs: Tailor-made solutions to meet your unique needs.

PRT Sensor Calibration Service from Process Parameters

Ensuring the accuracy of your Platinum Resistance Thermometers (PRTs) is crucial for maintaining optimal performance and reliability in your industrial applications. At Process Parameters, we offer a comprehensive PRT sensor calibration service designed to meet the stringent requirements of various industries.

Our calibration services utilise UKAS traceable equipment, ensuring that your PRT sensors deliver precise and reliable temperature measurements.

Whether you’re in manufacturing, chemical processing, or any other demanding environment, our expert team can calibrate your Pt100 and Pt1000 sensors to the highest standards. Contact us today to schedule your calibration service.

Industries and Applications

Our industrial platinum resistance thermometers are designed to meet the diverse needs of various industries and applications. From industrial manufacturing, construction, and machinery to chemical plants, food processing, and beyond, our high-quality temperature sensors provide accurate and reliable measurements in demanding environments.

Whether you need precise temperature control for production lines, monitoring of chemical reactions, or ensuring food safety, our sensors are built to withstand harsh conditions and deliver consistent performance.

Looking for a Custom Pt100 Platinum Resistance Thermometer?

At Process Parameters, we design and manufacture high-quality temperature sensors.

Our expert team is here to help you select the perfect platinum resistance thermometer for your application. We offer personalised guidance, competitive pricing, and exceptional customer support.

Contact us today for a free quote or to learn more about our platinum RTD sensors.

Call us at 01628 778788 or email sales@processparameters.co.uk

FAQs

What is an RTD Sensor?

An RTD sensor, or Resistance Temperature Detector, is a device used to measure temperature. An RTD probe works by sensing the change in the electrical resistance of a metal wire as the temperature changes.

This change in resistance is then converted into a temperature reading, providing high accuracy temperature measurements in various applications and industries.

Read more about ‘what is an RTD sensor?‘ here.

What is a Platinum Resistance Thermometer?

A Platinum Resistance Thermometer (PRT) is a type of temperature sensor that utilises the change in electrical resistance of platinum wire to measure temperature.

PRTs are known for their high accuracy, stability, and wide temperature range, making them ideal for various industrial, scientific, and metrology applications.

What is a Platinum Resistance Thermometer Used For?

Platinum resistance thermometers (PRTs) are used for precise temperature measurement in industrial applications, offering greater stability and accuracy than thermocouples or thermistors. They excel in environments requiring fast response time and vibration resistance. PRTs are crucial in calibration processes, HVAC systems, and scientific research, providing reliable readings from very low to high temperatures.

How Accurate is a Platinum Resistance Thermometer?

Platinum resistance thermometers offer exceptional accuracy, typically within ±0.1°C or better. Their high resistance and stable resistivity ensure precise measurements.

Calibrated in accordance with IEC standards, PRTs maintain accuracy across a wide temperature range. Professional knowledge and use of Fluke calibrators can further enhance their precision, minimising thermoelectric voltages and contamination effects.

What are the Advantages of Platinum Resistance Thermometer?

Platinum Resistance Thermometers offer numerous advantages, making them ideal for industrial applications. The platinum element used in PRTs provides a fast thermal response, ensuring accurate and quick temperature measurements. These thermometers excel in both very low temperatures and moderate temperatures, covering a wide temperature scale.

Unlike copper or nickel, the noble metal platinum offers exceptional stability and resistance to corrosion. The standard platinum resistance thermometer (SPRT) is renowned for its high accuracy, thanks to its precise RTD resistance characteristics.

The coil design of PRTs enhances their sensitivity and reliability, making them a preferred choice for demanding industrial environments. Additionally, comprehensive product manuals ensure easy installation and maintenance, further enhancing their practicality and effectiveness.

What is the Temperature Range of 100 ohm Platinum RTD?

A 100 ohm Platinum RTD (PT100) typically measures temperatures from -200°C to 850°C. Its nominal resistance at 0°C is 100 ohms, following a defined resistance relationship. Industrial RTDs with ceramic or PVC sheaths can withstand higher temperatures. The RTD’s resistance increases predictably with temperature, allowing accurate readings across this extensive range.

What is a Pt100 Temperature Sensor?

A PT100 temperature sensor is a type of platinum resistance thermometer (RTD) that uses a platinum wire with a resistance of 100 ohms at 0 degrees Celsius.

The resistance of the wire changes with temperature, allowing for accurate temperature measurement in a range of applications.

Read more about the PT100 temperature sensor working principle here.

What are the Types of RTD Sensors?

There are several types of RTD sensors commonly used, but the most popular type of RTD is a Pt100 or Pt1000 temperature sensor.

- PT100: It uses platinum wire with a resistance of 100 ohms at 0 degrees Celsius

- PT1000: Similar to PT100, but with a resistance of 1000 ohms at 0 degrees Celsius

The main difference between PT100 and PT1000 temperature sensors lies in their resistance values. PT100 and PT1000 are both types of platinum resistance temperature detectors (RTDs), which means they are made of platinum wire and their resistance changes with temperature.

The PT100 sensor has a resistance of 100 ohms at 0 degrees Celsius and follows a defined resistance-temperature relationship. It is commonly used in applications where high accuracy is required, such as scientific research, industrial process control, and laboratory equipment. PT100 sensors offer a higher resolution and greater sensitivity to temperature changes due to their smaller resistance change per degree Celsius.

On the other hand, the PT1000 sensor has a resistance of 1000 ohms at 0 degrees Celsius. PT1000 sensors are typically used in applications where a higher resistance is preferred. They are often chosen for their larger resistance change per degree Celsius, which can improve measurement accuracy in certain temperature ranges. PT1000 sensors are commonly found in HVAC systems, building automation, and general temperature monitoring applications.

When selecting between PT100 and PT1000 sensors, it is essential to consider the specific temperature range, accuracy requirements, and compatibility with the measurement system to ensure accurate and reliable temperature measurements.

What is an Ambient Air Temperature Sensor?

An Ambient Air Temperature Sensor is a device that measures the temperature of the surrounding air. It helps determine the temperature in the environment where it is installed, providing information for various purposes such as offices, HVAC systems, climate control systems in cars or weather monitoring equipment.

Platinum Resistance Thermometers (RTD Sensor, PRT, Pt100 Sensors, Pt1000)

RTD Pt100 Temperature Sensor PPL3-P, IP68 KNE Terminal Head, 4-20mA Transmitter

Platinum Resistance Thermometers (RTD Sensor, PRT, Pt100 Sensors, Pt1000)

Platinum Resistance Thermometers (RTD Sensor, PRT, Pt100 Sensors, Pt1000)

Platinum Resistance Thermometers (RTD Sensor, PRT, Pt100 Sensors, Pt1000)

Platinum Resistance Thermometers (RTD Sensor, PRT, Pt100 Sensors, Pt1000)

Platinum Resistance Thermometers (RTD Sensor, PRT, Pt100 Sensors, Pt1000)

Platinum Resistance Thermometers (RTD Sensor, PRT, Pt100 Sensors, Pt1000)

PRT Process Connection Thread & Terminal Head Probe – PPL4-P

Platinum Resistance Thermometers (RTD Sensor, PRT, Pt100 Sensors, Pt1000)

Platinum Resistance Thermometers (RTD Sensor, PRT, Pt100 Sensors, Pt1000)

Platinum Resistance Thermometers (RTD Sensor, PRT, Pt100 Sensors, Pt1000)

Platinum Resistance Thermometers (RTD Sensor, PRT, Pt100 Sensors, Pt1000)

High Accuracy RTD Pt100 Temperature Sensor – 4 wire 1/10 DIN – PPL1-P

Platinum Resistance Thermometers (RTD Sensor, PRT, Pt100 Sensors, Pt1000)

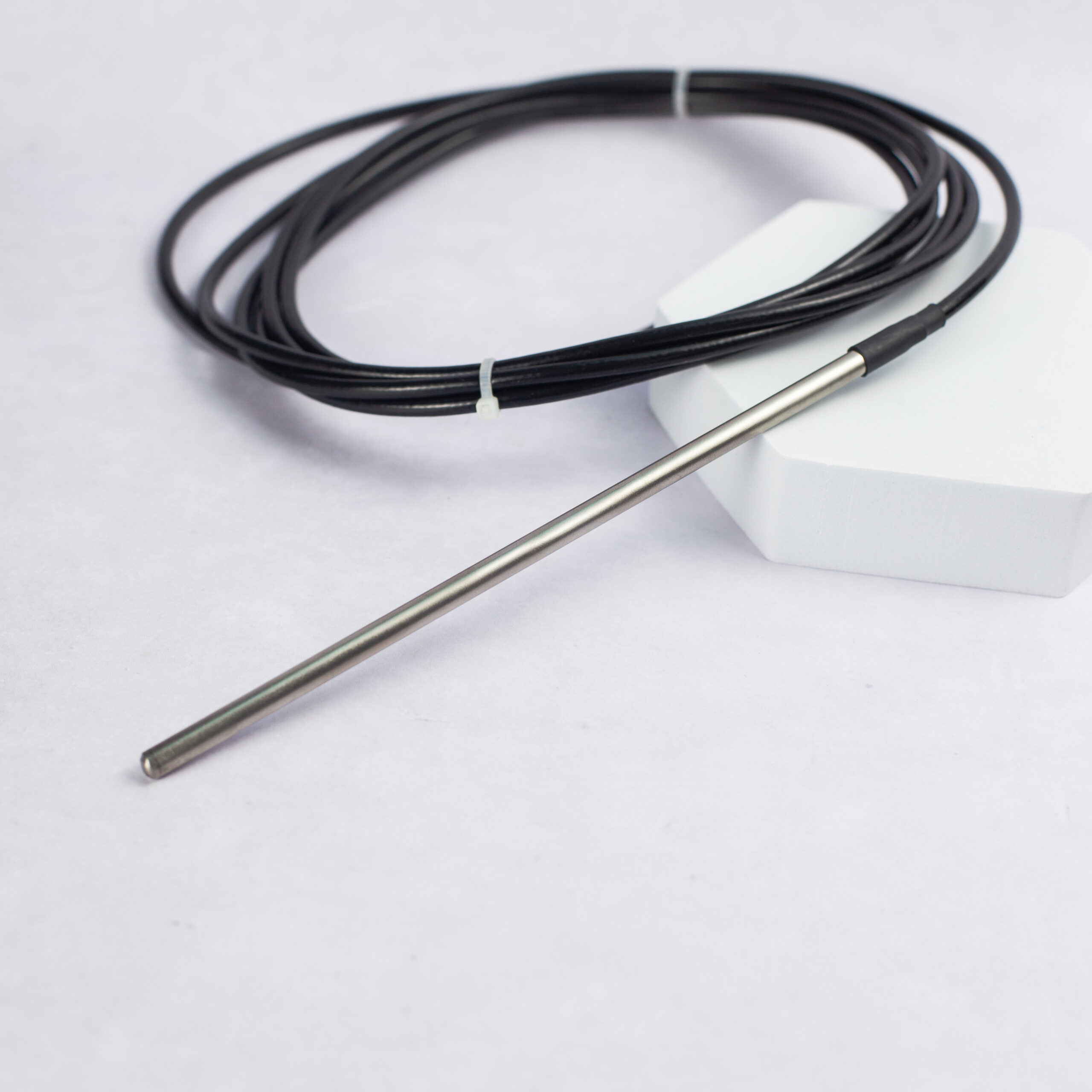

RTD Pt100 Probe Temperature Sensor with PTFE Flying Lead – PPL1-P

Platinum Resistance Thermometers (RTD Sensor, PRT, Pt100 Sensors, Pt1000)

Industrial RTD Pt100 Temperature Sensor Probe with KNE Terminal Head – PPL3 RTD Sensor