What is a Pressure Transmitter? Ultimate Guide

What is a Pressure Transmitter?

A pressure transmitter is a device used to measure pressure and convert it into an electrical signal.

Commonly used in a variety of industries, including oil and gas, chemical, and manufacturing, pressure transmitters are an essential component of many systems.

From monitoring the pressure of a gas in a pipeline to measuring the pressure of a liquid in a tank, they provide accurate and reliable pressure readings that are used to control and monitor processes.

As technology continues to advance, pressure transmitters are becoming more accurate, reliable, and versatile, making them an essential tool for many industries.

In this guide, we cover everything you need to know about pressure transmitters including:

- How they work

- Different types of pressure transmitters

- Components

- Uses and applications

- How to choose a pressure transmitter

Let’s dive in.

How Does a Pressure Transmitter Work?

The basic function of a pressure transmitter is to measure the pressure of a fluid or gas and convert it into an electrical signal. This signal can then be transmitted to a control system or display device for further analysis.

The transmitter works by detecting changes in pressure and converting them into changes in resistance, capacitance, or other electrical properties. These changes are then amplified and converted into a standard output signal, such as 4-20 mA or 0-10 VDC.

Often used in conjunction with other sensors and control devices, they provide a complete system for monitoring and controlling processes.

There are different types of pressure sensors used in pressure transmitters such as strain gauge, capacitive, piezoelectric, and resonant.

Strain gauge sensors are the most commonly used and are based on the principle that the resistance of a metal changes when it is subjected to strain.

Capacitive sensors measure the change in capacitance between two plates when the pressure changes. Piezoelectric sensors generate an electrical charge when subjected to pressure. Resonant sensors use the natural frequency of a vibrating element to measure pressure.

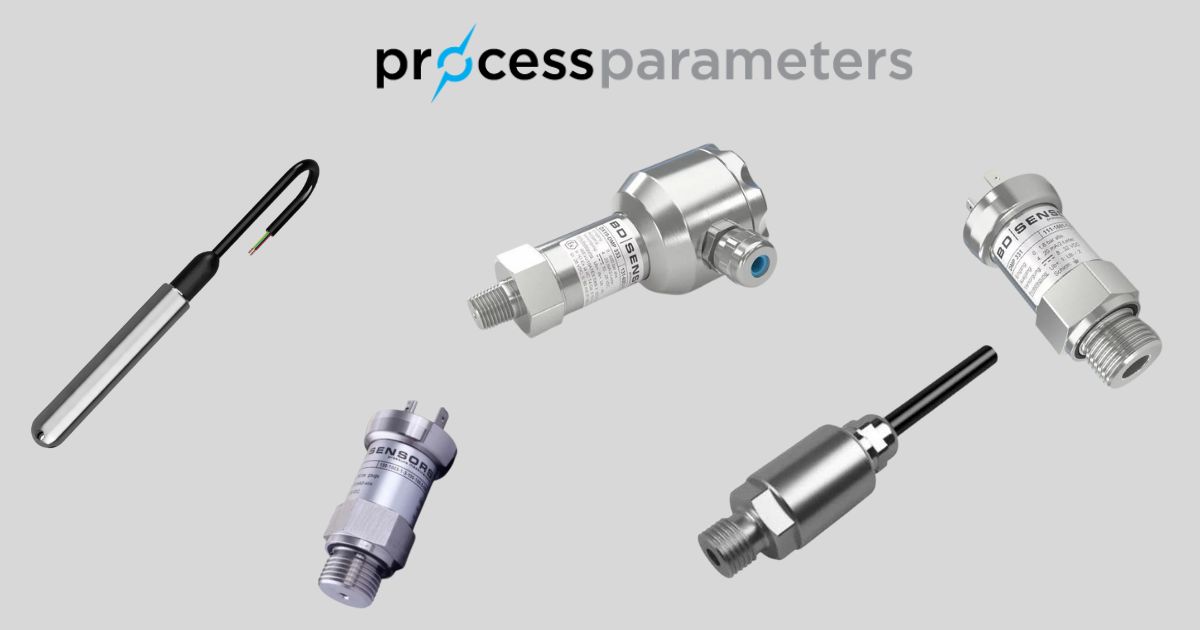

Our team at Process Parameters has extensive knowledge and experience in temperature management and process control.

Browse our pressure transmitters, submersible level transmitters and level sensors. If you have any questions, please get in touch.

Pressure & Level Sensors

DMP333 High Range ATEX IECEX Pressure Transmitter 100 bar to 600 bar

Pressure & Level Sensors

DMP331 Low Range Atex IECEX Pressure Transmitter 100 mbar to 60 bar

Difference Between a Pressure Transmitter, Pressure Sensor and Pressure Transducer

Pressure sensors, pressure transducers, and pressure transmitters are all devices used to measure pressure, but they have different characteristics and applications.

A pressure sensor usually provides a millivolt output signal, a transducer offers an amplified voltage output, and a transmitter typically delivers a 4-20mA output signal.

Pressure Measurement

Pressure transmitters can measure different types of pressure such as gauge pressure, absolute pressure, and differential pressure.

Absolute Pressure Transmitters

Absolute pressure transmitters measure pressure relative to a perfect vacuum. They are typically used in applications where the reference pressure is zero, such as in vacuum systems.

Absolute pressure transmitters are often used in the chemical and pharmaceutical industries, where precise pressure measurement is critical for process control.

Gauge Pressure Transmitters

Gauge pressure transmitters measure pressure relative to atmospheric pressure. They are the most common type of pressure transmitter and are used in a wide range of applications, including HVAC systems, pneumatic systems, and hydraulic systems.

Gauge pressure transmitters are also used in the oil and gas industry to measure the pressure of gases and liquids in pipelines.

Differential Pressure Transmitters

Differential pressure transmitters measure the difference in pressure between two points. They are commonly used in flow measurement applications, such as in the measurement of fluid flow through pipes.

Differential pressure transmitters are also used in the measurement of level, density, and viscosity.

Multivariable Pressure Transmitters

Multivariable pressure transmitters measure multiple parameters, such as pressure, temperature, and flow rate, using a single device.

They are often used in applications where multiple parameters need to be measured simultaneously, such as in the chemical and petrochemical industries.

Multivariable pressure transmitters can provide a cost-effective solution for measuring multiple parameters in a single device.

Related: What is Pressure Measurement?

Components of a Pressure Transmitter

The basic components of a pressure transmitter include a pressure sensor, a signal conditioning circuit, and an output circuit.

The pressure sensor is responsible for converting the pressure into a mechanical displacement, which is then converted into an electrical signal by the signal conditioning circuit. The output circuit amplifies the signal and transmits it to the control system.

Applications of Pressure Transmitters

Process Industries

Pressure transmitters are widely used in process industries such as oil and gas, chemical, and food and beverage. In these industries, pressure transmitters are used to monitor and control pressure in pipelines, tanks, and vessels.

Pressure transmitters help to ensure the safety and reliability of process equipment and reduce downtime.

Automotive Industry

Pressure transmitters are used in the automotive industry for a variety of applications such as measuring the pressure of tyres, engine oil, fuel, and air.

Pressure transmitters are also used in the hydraulic systems of vehicles, such as brakes and suspension.

Aerospace and Aviation

Pressure transmitters are critical components in the aerospace and aviation industries. They are used to measure the altitude, airspeed, and cabin pressure of aircraft. They also monitor the pressure of hydraulic systems and fuel tanks.

Marine Applications

Pressure transmitters measure the pressure and liquid levels in offshore oil and gas exploration, shipping, and fishing.

They are used to measure the pressure of seawater, oil, and gas in pipelines, vessels and tanks.

At Process Parameters, our team can help you select the best type of sensor for your application. Get in touch with our experts for more information.

Get in TouchHow to Choose a Pressure Transmitter

Here are three important things to consider when selecting a pressure transmitter.

1. Accuracy

Accuracy refers to how closely the transmitter’s output matches the actual pressure being measured. This is typically expressed as a percentage of the full-scale range of the transmitter.

For example, a transmitter with a full-scale range of 100 psi and an accuracy of ±0.5% would have an accuracy of ±0.5 psi.

2. Pressure Range

Range refers to the minimum and maximum pressure that the transmitter is capable of measuring.

The range is typically expressed in units of pressure, such as psi, bar, or kPa.

It is important to choose a transmitter with a range that is appropriate for the application, since a transmitter with too small a range may not be able to measure the required pressure, while a transmitter with too large a range may not be as accurate.

3. Stability

The stability of a pressure transmitter refers to how well it maintains its accuracy over time.

This is important in applications where the pressure being measured may change slowly over time, such as in a chemical process. Stability is typically expressed as a percentage of the full-scale range per year.

For example, a transmitter with a full-scale range of 100 psi and a stability of ±0.1% per year would have a stability of ±0.1 psi per year.

Pressure Transmitters from Process Parameters

Pressure transmitters are essential components in various industries, helping to ensure the safety, reliability, and efficiency of equipment and operations.

As temperature measurement specialists, we offer a range of pressure transmitters suited to a range of industrial applications.

Not sure which transmitter is best for your application? Get in touch with our expert team who will be happy to help you find the right product for your requirements and specifications.

Get a QuotePressure & Level Sensors

DMP333 High Range ATEX IECEX Pressure Transmitter 100 bar to 600 bar

Pressure & Level Sensors

DMP331 Low Range Atex IECEX Pressure Transmitter 100 mbar to 60 bar

Other Knowledge Guides:

- What is a Pressure Sensor?

- What is a Level Sensor?

- What is Pressure Measurement?

- What is a Data Logger?

- What Is A Temperature Sensor?

- What is a Thermowell?

- What is a Thermistor?

- What is a Temperature Transmitter?

- What is an RTD Sensor?