What is a Thermowell? Types, Materials & Uses

Why are Thermowells Essential in Temperature Measurement?

Temperature measurement is a critical aspect of various industrial processes, ranging from chemical manufacturing to food production. To achieve accurate and reliable temperature readings, engineers and technicians often employ specialised devices like thermowells.

Process Parameters are an expert manufacturer of custom-built thermowell pockets. We also provide industrial temperature sensors including thermocouples, Pt100 temperature sensors, level transmitters, and temperature transmitters.

In this blog post, we’ll jump into the world of thermowells, exploring what they are, their purpose, types, materials, installation, and more.

Before we begin, what is a thermowell?

What Is a Thermowell Sensor?

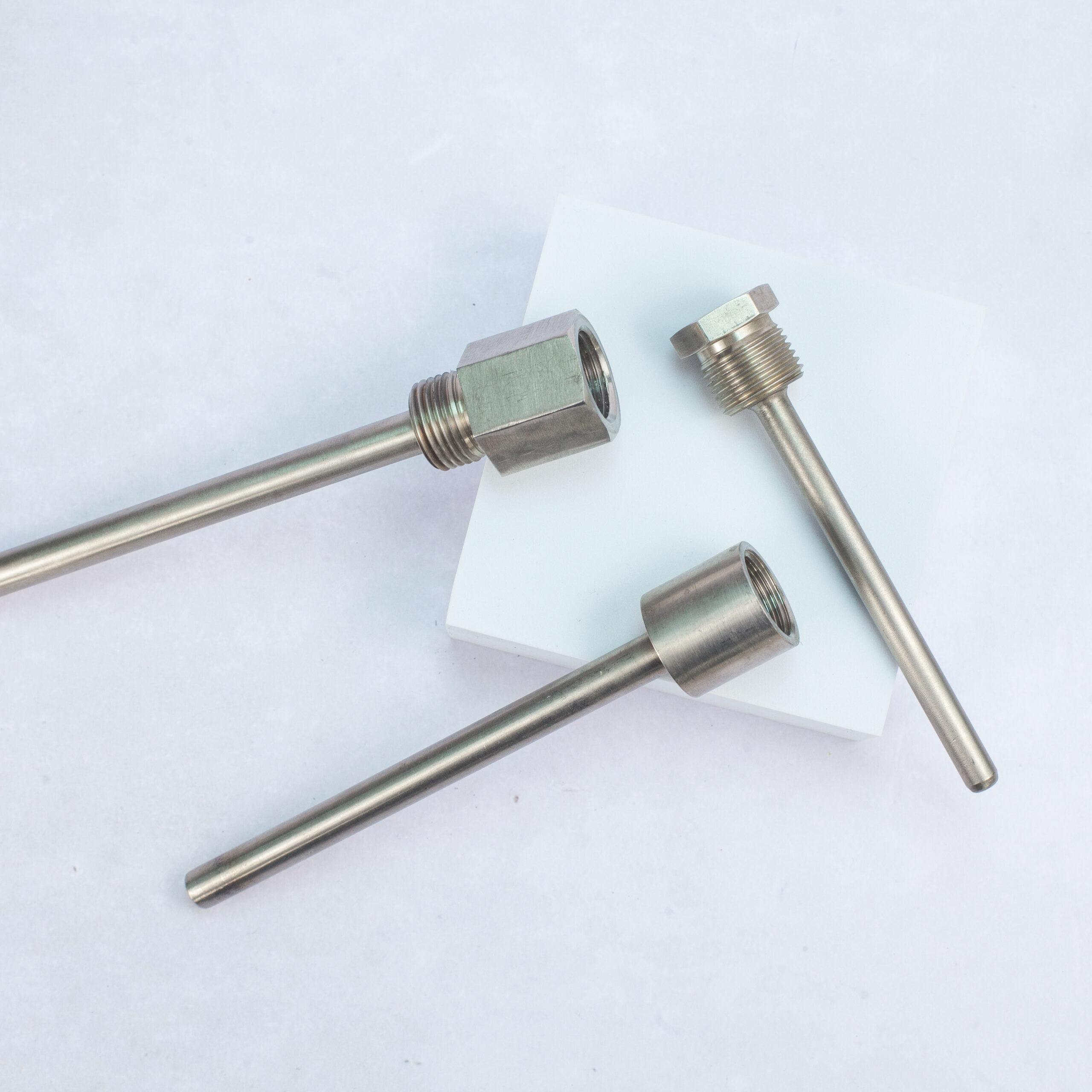

A thermowell is a protective sheath or enclosure designed to house a temperature sensor (usually a thermometer or thermocouple) within a process or fluid. It acts as a barrier between the sensor and the harsh environment, ensuring that the sensor remains intact and functional even when subjected to extreme conditions.

The Purpose of Thermowells in Temperature Measurement

Thermowells serve several vital purposes in temperature measurement:

- Protection: They shield temperature sensors from corrosive, abrasive, or high-pressure substances, extending their lifespan.

- Accessibility: Thermowells allow for easy access to the sensor for calibration, replacement, or maintenance without interrupting the process.

- Isolation: They isolate the sensor from the process fluid, preventing contamination and ensuring accurate temperature readings.

Thermowell Types

Thermowell sensors come in various types, each suited to specific applications:

Threaded Thermowells

These are screwed into a threaded socket or fitting, making them easy to install and remove.

Flanged Thermowells

Designed with flanges, these are suitable for applications requiring frequent removal.

Socket Weld Thermowells

These are welded directly into the process pipeline, offering robust and permanent installation.

Sanitary Thermowells

Used in the food, pharmaceutical, and biotechnology industries, they feature a hygienic design to meet strict sanitation standards.

Pocket Sensor

A cylindrical fitting with a tube closed at one end and mounted on the wall of the piping or vessel.

At Process Parameters, we offer custom-built, high-quality thermowell pockets to suit your thermocouple or platinum resistance thermometer with a simple design. Choose your pocket diameter, pocket length and thread type and we’ll do the rest.

If you’re not sure what you need for your application, please get in touch and we can help identify your requirements.

Get in TouchBrowse thermowells available from Process Parameters.

Thermowells / Pockets

Temperature Probes & Sensors

Thermowell Materials: Choosing the Right One for Your Application

The choice of thermowell material is crucial for performance and durability. Common materials include:

Stainless Steel (304/316/321):

- Advantages: Stainless steel is a popular choice due to its corrosion resistance, making it suitable for a wide range of applications. It is durable, easy to clean, and relatively cost-effective.

- Applications: Stainless steel thermowells are commonly used in chemical processing, food and beverage, HVAC systems, and pharmaceutical industries.

Inconel:

- Advantages: Inconel alloys (e.g., Inconel 600 and Inconel 800) are known for their exceptional resistance to high-temperature and corrosive environments. They provide excellent mechanical strength and durability.

- Applications: Inconel thermowells are often used in petrochemical, aerospace, and power generation industries where extreme conditions are prevalent.

Hastelloy:

- Advantages: Hastelloy alloys (e.g., Hastelloy C276) offer outstanding resistance to a wide range of corrosive chemicals, acids, and chlorides. They are suitable for highly corrosive media.

- Applications: Hastelloy thermowells are commonly found in chemical processing, oil and gas, and pharmaceutical industries where aggressive substances are present.

Ceramic:

- Advantages: Ceramic thermowells are preferred for applications involving extremely high temperatures and pressures. They exhibit excellent thermal stability and resistance to wear.

- Applications: Ceramic thermowells are used in industries like metallurgy, glass manufacturing, and semiconductor processing.

Plastics (Teflon, PVC, PTFE):

- Advantages: Plastic thermowells are resistant to corrosion and are often used in mildly corrosive environments. They are also lightweight and cost-effective.

- Applications: These materials are suitable for applications in the chemical, pharmaceutical, and water treatment industries.

Brass and Copper:

- Advantages: Brass and copper thermowells are good conductors of heat and are cost-effective options for lower-temperature applications.

- Applications: They are often used in HVAC systems, plumbing, and less demanding industrial processes.

Exotic Alloys:

- Advantages: Exotic alloys like Monel and Titanium are chosen for specific applications where a combination of corrosion resistance and high-temperature capabilities is required.

- Applications: These materials find use in offshore oil and gas, marine, and aerospace industries.

Selecting the right thermowell material is essential to ensure the longevity and reliability of temperature measurement systems. Factors such as temperature range, pressure, chemical compatibility, and budget constraints should all be considered when making this decision.

Consulting with our experts will help in determining the most suitable thermowell material for your given application.

Contact UsThermowell Installation and Maintenance

Proper installation and maintenance are essential for the longevity and accuracy of thermowells. Ensuring proper alignment and orientation during installation is the first step to long-term accurate results.

After that, regularly inspect for signs of corrosion or damage, and schedule routine calibration to maintain accuracy.

At Process Parameters, we offer an in-house calibration service. Contact us for more details.

Thermowells vs. Direct Temperature Sensors: Pros and Cons

There are pros and cons of thermowell temperature sensors and direct temperature sensors depending on your needs and application.

To help you make the best decision for your requirements, we’ve put together this table below.

| Aspect | Thermowells | Direct Temperature Sensors |

| Protection | Excellent | Limited by environmental conditions |

| Accessibility | Easy maintenance and replacement | Often requires process shutdown |

| Isolation | Effective isolation from process | Direct contact with process fluid |

| Installation | Relatively straightforward | May require complex mounting |

| Cost | Additional cost for thermowell | Lower initial cost |

What is a Thermowell Used For?

Thermowells are indispensable across a wide range of industries. They serve as protective barriers that enable accurate and reliable temperature monitoring while withstanding challenging environmental conditions and maintaining process integrity.

Here are some of the applications a thermowell is used for:

Protection from Harsh Environments

Thermowells shield temperature sensors from corrosive, abrasive, or otherwise hostile process fluids, gases, or solids. This protection prevents sensor damage, extends their lifespan, and ensures continued accuracy.

Isolation from Process Media

Thermowells isolate temperature sensors from direct contact with the process medium. This isolation is crucial to prevent contamination of the sensor, maintain measurement accuracy, and avoid chemical reactions between the sensor and the medium.

Facilitating Sensor Maintenance and Replacement

Thermowells provide easy access to temperature sensors for calibration, maintenance, or replacement without the need to shut down the entire process. This accessibility reduces downtime and operational disruptions.

Temperature Measurement in High-Pressure Applications

In high-pressure environments, thermowells are used to house temperature sensors. These environments can be found in oil and gas processing, chemical manufacturing, and power generation, among others.

Temperature Control in Industrial Processes

Thermowells are crucial for temperature control and monitoring in various industrial processes, ensuring that the desired temperature is maintained for product quality, safety, and process efficiency. This is particularly important in chemical, pharmaceutical, and food processing industries.

Safety and Compliance

In industries such as nuclear power, petrochemical, and aerospace, where safety and compliance with regulatory standards are paramount, thermowells are used to meet stringent requirements for accurate and reliable temperature measurement.

Preventing Sensor Contamination

In sanitary and hygienic applications like food and beverage processing and pharmaceutical manufacturing, thermowells maintain the integrity of temperature sensors by preventing contact with potentially contaminating substances.

High-Temperature Applications

Thermowells are used in high-temperature environments, such as those found in metal smelting, glass manufacturing, and combustion processes. They protect sensors from extreme heat and thermal cycling.

Monitoring and Control in HVAC Systems

In heating, ventilation, and air conditioning (HVAC) systems, thermowells help regulate temperature and ensure indoor comfort by protecting sensors in ducts, pipes, and air handling units.

Research and Laboratory Settings

Thermowells are employed in research and laboratory environments to protect temperature sensors used in experiments and scientific studies where accurate temperature measurement is critical.

Environmental Monitoring

Weather stations and environmental monitoring systems use thermowells to house sensors for measuring temperature accurately in various weather conditions.

Oil Well and Reservoir Monitoring

In the oil and gas industry, thermowells are used in downhole applications to measure temperature and pressure within oil wells and reservoirs.

Water Treatment and Utilities

Thermowells help maintain precise temperature control in water and wastewater treatment plants, ensuring effective treatment processes and compliance with environmental regulations.

Conclusion: What is a Thermowell Temperature Sensor

Thermowells are essential components in temperature measurement, offering protection, isolation, and accessibility. Understanding their types, materials, installation, and maintenance is crucial for accurate and reliable temperature monitoring in various industries.

By employing thermowells effectively, you can enhance process control and safety while extending the lifespan of your temperature sensors.

And remember, here at Process Parameters, we provide custom-built, high-quality thermowell pockets. Simply choose your pocket diameter, pocket length and thread type and we’ll do the rest.

If you’re not sure what you need, or you’d like a free quote, please get in touch.

Request a QuoteBrowse thermowell pockets available from Process Parameters.

Thermowells / Pockets

Temperature Probes & Sensors

What is a Thermowell FAQs

What materials are used for thermowells?

- Stainless Steel: Resistant to corrosion, making it suitable for various applications.

- Inconel: Ideal for high-temperature and corrosive environments.

- Hastelloy: Excellent for highly corrosive media, such as acids and chlorine.

- Ceramic: Used in extreme temperature and pressure conditions.

What are thermowells used for?

Thermowells protect temperature sensors (such as thermometers, thermocouples, and resistance temperature detectors). These are protective enclosures which ensure the accuracy, longevity, and safety of temperature measurements in a wide range of industries.

What industries use thermowells?

- Chemical processing

- Oil and gas production

- Food and beverage

- Pharmaceuticals

- HVAC systems

- Power generation