Infrared Thermometer: How to Use for Enhanced Accuracy in Industrial Settings

Full Guide and Tips: How to Use An Infrared Camera

Temperature is a critical parameter in industrial processes and manufacturing, for obvious reasons.

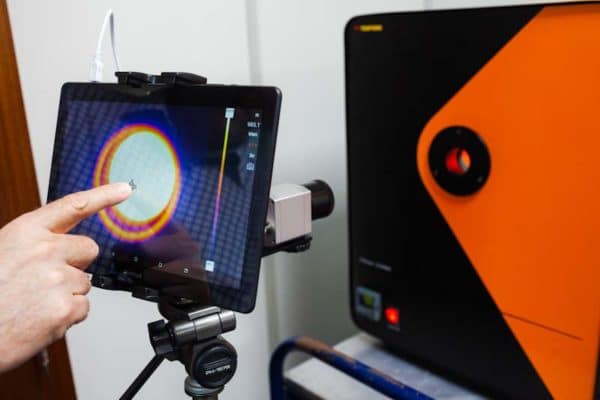

Precise temperature control and measurement ensures product quality, operational efficiency, and safety. Infrared (IR) thermometers provide non-contact temperature measurement and are therefore widely used across industrial facilities.

However, proper techniques are required for accurate results. How you use infrared thermometers is crucial to the accuracy and consistency of your results.

This guide focuses on best practices for using infrared thermometers in industrial settings.

It covers the basics of how these devices work, steps for proper usage, applications in manufacturing processes, tips for professionals, and safety guidelines.

Interested in purchasing an infrared thermometer for your business? At Process Parameters, we are a leading distributor of Optris thermal imaging cameras and infrared thermometers supplying to companies within the UK, Ireland and worldwide.

View our range of IR cameras or contact us for a free quote.

Send An EnquiryGeneral Purpose IR Thermometers

General Purpose IR Thermometers

General Purpose IR Thermometers

How to Use an Infrared Thermometer

1. Properly Prepare for Temperature Measurement

- Ensure a clear line of sight between the device and the target

- Set necessary parameters like emissivity

- Allow enough distance between the thermometer and the object

2. Follow Best Practices for Accurate Readings

- Hold the thermometer perpendicular to the surface

- Make sure the target area falls within the device’s spot size

- Take multiple readings in different areas for average values

- Avoid surfaces with high infrared reflectivity

- Ensure objects have reached thermal equilibrium

3. Avoid Common Mistakes

- Measuring through transparent surfaces like glass or plastic

- Not considering environmental factors like wind and moisture

- Neglecting emissivity changes from rust, residue or other alterations

4. Calibrate Your Infrared Thermometers

Periodic calibration ensures sustained accuracy.

- Calibrate against verified reference sources

- Adjust equipment to match standard values

- Log calibration data for traceability

At Process Parameters, we offer a professional temperature calibration service.

5. Interpret Your Data for Process Optimisation

- Log all measurements for historical records

- Identify patterns signalling problems

- Correlate data with other process parameters

- Quantify energy loss for upgrade justification

6. Use Proper Handling and Maintenance

- Avoid exposing the device to physical impact

- Keep lens clean and free of scratches

- Check battery indicator and replace as needed

7. Follow Safety Protocols in Industrial Environments

- Follow lockout procedures before equipment inspection

- Use appropriate personal protective equipment

- Measure dangerous objects like extremely hot materials with caution

Infrared Thermometers in Industrial Applications

Infrared thermometers instantly measure surface temperature from a distance. They detect infrared energy emitted from objects and convert readings into temperature values.

Industrial infrared thermometers feature durable designs for harsh environments. Different models offer various infrared spectral ranges, distance-to-spot ratios, response times and other features.

Read our guide for more information about how infrared thermometers work.

Importance of Accurate Temperature Measurement

Temperature affects chemical reactions, physical properties, and biological processes. Even small temperature variations in industrial settings can significantly impact product characteristics and plant efficiency.

By accurately measuring temperature, issues can be quickly identified and processes optimised. Infrared thermometers are thus vital for quality management.

Head to our guide for more information about infrared thermometer accuracy.

Temperature Monitoring in Manufacturing Processes

Infrared cameras have many applications in manufacturing:

- Monitoring bearing and motor temperatures

- Scanning for overheating electrical systems and connections

- Spot-checking fluid tanks, pipes and vessels

- Mapping thermal distribution in ovens and furnaces

- Quality Control and Maintenance Applications

- Regular inspection of heat exchangers

- Identification of efficiency issues like steam leaks

- Post-maintenance verification of equipment

- Monitoring of critical zones in CNC machining

Basic Working Principle of IR Cameras

Infrared thermometers measure surface temperature without contact. The device optics focus infrared energy onto a detector, which generates signals based on the amount of radiation.

This data is converted into temperature readings using internal calibration algorithms. The results are instantly displayed.

Read our in-depth guide on what an infrared thermometer is here.

Types of Infrared Thermometers in Industry

Common types include handheld and fixed-mount infrared thermometers. Handheld models provide portable spot measurement, while fixed units feature remote measurements of stationary equipment.

Speciality models like line scanners measure temperature distribution across surfaces. Models range from compact to heavy-duty designs.

Contact our temperature measurement specialists for expert recommendations on selecting the right infrared thermometer or thermal camera for your facility. We provide free quotes along with technical guidance to build the best solution for enhanced operations and safety.

Recap of How to Use an Infrared Camera

Infrared cameras boost productivity and quality when used properly. Follow usage guidelines for precise industrial temperature monitoring. Prioritise safety with equipment handling and around operational processes.

Learn your device’s capabilities for the application. Seek additional training if needed to promote reliable and secure data collection. With proper infrared thermometer use, industrial facilities can achieve new levels of efficiency and product quality.

Best Infrared Thermometers and Thermal Cameras

At Process Parameters, we supply the highest quality infrared thermometers and thermal imaging cameras from Optris across the UK, Ireland and worldwide.

Our product range caters to various industries including HVAC, manufacturing, R&D and more.

The Optris line features cutting-edge infrared technology for precise non-contact temperature measurement. The diverse thermometers and thermal cameras have advanced optics, detectors and on-board processing.

Models are available for short, mid and long-range monitoring. Speciality devices provide 2D scanning and mapping of thermal patterns. The product series contains compact handheld and fixed-mount instruments and advanced imaging systems.

We carry Optris devices suited for:

- HVAC inspection and diagnostics

- Process control in manufacturing

- Maintenance of mechanical equipment

- Electrical inspection and failure prevention

- Product quality testing

- Building envelope analysis

- Fire prevention systems

- Many other applications

Our engineers can work with you to develop and manufacture custom designs of temperature sensors. Speak to the team.

Send us an email at sales@processparameters.co.uk, call 01628 778788, or complete our online enquiry form.

Send An EnquiryGeneral Purpose IR Thermometers

General Purpose IR Thermometers

General Purpose IR Thermometers

Infrared Thermometer Usage Guide FAQs

How often should I calibrate my infrared thermometer?

We recommend calibrating your infrared thermometer every 6-12 months to maintain accuracy. Calibrate more frequently if the device is subjected to heavy use or extreme environments. Keep a log to track calibration history.

What is the best infrared thermometer for the food industry?

Look for infrared thermometers designed specifically for the food industry that meet regulatory standards. Ensure the device can handle high humidity environments and has the appropriate temperature measurement range and optical resolution for scanning cooked/prepared foods. Sanitary design is also an important factor.

Can infrared thermometers be used through glass or plastic?

Infrared thermometers measure the surface temperature of opaque materials. Readings through transparent surfaces like glass or plastic will measure the temperature of whatever is behind them instead. However, speciality infrared thermometers exist for low-emissivity surface measurement through transparent barrier films.

Related Knowledge Guides:

- Can a Thermal Camera See Through Walls?

- How to Improve Manufacturing with an Industrial Camera

- How Does a Thermal Imaging Camera Work?

- How Accurate are Infrared Thermometers?

- Using a Thermal Camera to Detect Heat Loss

- Choosing an Infrared Pyrometer

- What is a Pyrometer?

- What is Thermal Scanning?

- What is a Machine Vision Camera?

- Why is a Pin Sharp Thermal Image Important?

- How Can a Thermal Imaging Camera Become Part of Your Process?

- Can You Improve Your Thermal Efficiency With Imaging Cameras?

- Pyrometer or IR Camera?

- How Does an Infrared Thermometer Work?

- Guide to Infrared Thermometer Calibration