How Accurate Are Infrared Thermometers?

Infrared Thermometer Accuracy

Infrared thermometers are popular for their non-contact temperature measurement capabilities. They offer a convenient, safe and hygienic method of gauging temperature in various fields, including healthcare and industrial applicaations. Ensuring accurate readings with infrared thermometers is essential for maintaining their reliability and effectiveness.

In this article, we explore:

- What infrared thermometers are

- How they work

- Benefits and limitations

- Factors influencing IR thermometer accuracy

- Methods for improving and verifying their accuracy

Infrared Thermometers

What is an Infrared Thermometer?

An infrared thermometer, also known as an IR thermometer, is a non-contact temperature sensor used to measure temperature without physical contact.

It detects and captures the thermal radiation emitted by an object, converting it into a temperature reading. Infrared temperature sensors are typically handheld devices with a laser pointer to assist in aiming at the target area.

Read our in-depth guide on what is an infrared thermometer here.

How do Infrared Thermometers Work?

Infrared thermometers operate based on the principle of infrared radiation. All objects above absolute zero emit infrared radiation, which increases or decreases with changes in temperature. These temperature sensors utilise a detector that senses the infrared radiation emitted by an object and converts it into an electrical signal. The signal is then processed and displayed as a temperature reading on the device.

What are the Benefits of Using Infrared Thermometers?

Non-contact measurement

Infrared thermometers offer a hygienic and non-invasive method of temperature measurement. They can be used from a safe distance, reducing the risk of cross-contamination and allowing measurements to be taken quickly and efficiently.

Instantaneous results

With an infrared sensor, temperature readings can be obtained almost instantly, providing immediate feedback without the need for physical contact or waiting time.

Wide range of applications

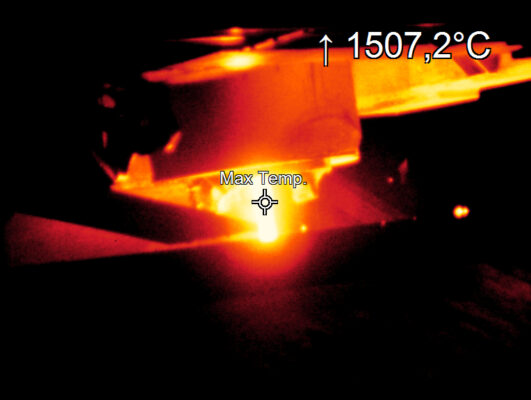

Infrared pyrometers are useful in fields such as healthcare, industrial applications, HVAC (Heating, Ventilation, and Air Conditioning), food safety, and more. Specific examples include monitoring body temperature, detecting hotspots in electrical systems, assessing mechanical equipment, finding faulty insulation, and ensuring food safety.

We are the leading UK distributor for Optris, a manufacturer of infrared thermometers and thermal imaging cameras for applications such as metals, plastics and glass. Contact our team to discuss your application and find out how a non-contact temperature sensor can improve your process.

Contact UsGeneral Purpose IR Thermometers

General Purpose IR Thermometers

General Purpose IR Thermometers

What are the Limitations of Using Infrared Thermometers?

Surface temperature measurement

IR sensors measure the temperature of the surface of an object which may not correlate with the internal temperature. This means infrared might not be completely accurate for certain applications, such as determining the core temperature of food or monitoring the temperature of delicate electronic components.

Environmental factors

Environmental conditions, including ambient temperature, humidity, and air movement, can affect the accuracy of infrared thermometer readings. These factors can influence the emitted and reflected infrared radiation, leading to potential inaccuracies.

Reflective surfaces

Infrared thermometers may struggle to provide accurate measurements on reflective or shiny surfaces as they can reflect ambient radiation, leading to inaccurate readings. In such cases, using a dull surface or applying a non-reflective material can help improve accuracy.

Accuracy of Infrared Thermometers

Factors that Affect the Accuracy of Infrared Thermometers

Distance-to-spot ratio (D:S ratio)

The D:S ratio specifies the size of the measurement area in relation to the distance from the object being measured. A smaller D:S ratio allows for more accurate readings of smaller areas, while a larger D:S ratio provides a wider coverage area but may sacrifice precision.

Emissivity settings

The emissivity setting of an infrared temperature sensor determines how effectively it can measure the radiation emitted by different materials. Adjusting the emissivity setting to match the surface being measured can enhance accuracy.

Temperature range

Different infrared thermometers have specific temperature ranges within which they provide optimal accuracy. Going beyond or below these ranges can lead to decreased precision and reliability.

How to Improve the Accuracy of Infrared Thermometer Readings

Proper calibration

Regular calibration of infrared thermometers is crucial for maintaining accuracy. Calibration ensures that the device provides consistent and reliable temperature readings. Manufacturers or accredited calibration facilities can perform calibration procedures.

At Process Parameters, we offer a comprehensive in-house calibration service. If you’d like more information, or a free quote, please get in touch.

Contact UsCorrect usage technique

Following the manufacturer’s instructions and guidelines for using the infrared thermometer is essential. This includes maintaining the recommended distance, aiming the sensor correctly, and considering the impact of environmental factors.

Minimise interferences

To minimise the influence of external factors, it is important to keep the target area clean, remove any obstacles or reflective materials, and ensure a stable and controlled environment whenever possible.

How to Check the IR Thermometer Accuracy

Ice bath method: The ice bath method involves placing the thermometer in an ice bath and verifying that it reads 0°C (32°F). This simple and accessible technique allows users to check the accuracy of their infrared sensor at a lower temperature range.

Reference heat source: Comparing the readings of the infrared thermometer with a reference heat source, such as a calibrated contact thermometer, can provide an indication of its accuracy at higher temperature ranges.

IR Thermometer Accuracy: A Summary

Infrared thermometers offer numerous benefits for temperature measurement in various fields. While they provide quick and convenient readings, understanding their limitations and ensuring accuracy is essential.

Factors such as distance-to-spot ratio, emissivity settings, and environmental conditions can influence the accuracy of IR sensor readings. By following proper usage techniques, regular calibration, and performing accuracy checks, users can improve the reliability of these devices and enhance their effectiveness in applications ranging from healthcare to industrial settings.

Recommendations for Using Infrared Thermometers

- Follow manufacturer’s instructions: Adhering to the guidelines provided by the manufacturer ensures proper usage of infrared thermometers and helps optimise accuracy.

- Regular calibration: Schedule regular calibration of infrared thermometers to maintain accuracy and consistency in temperature readings.

- Consider environmental factors: Be aware of the impact of environmental conditions such as temperature, dust, steam, humidity, and air movement, and minimise their influence on accuracy whenever possible.

- Verify accuracy periodically: Perform accuracy checks using the ice bath method or by comparing readings with a calibrated reference heat source to ensure the infrared thermometer’s reliability.

If you’d like more information about how an infrared temperature sensor can improve your process, get in touch with our friendly team.

For further information or a free quote, please email us at sales@processparameters.co.uk or call 01628 778788.

Send An EnquiryGeneral Purpose IR Thermometers

General Purpose IR Thermometers

General Purpose IR Thermometers

FAQs

Are infrared thermometers more accurate?

The accuracy of infrared thermometers can vary depending on the quality of the device, proper usage technique, and environmental conditions. When used correctly, infrared thermometers can provide accurate temperature measurements. However, it’s important to note that they measure surface temperature and may not always accurately represent the internal temperature of an object.

What are the pros and cons of infrared thermometers?

Pros of Infrared Thermometers:

- Non-contact measurement: Infrared thermometers offer a hygienic and non-invasive way to measure temperature, reducing the risk of cross-contamination.

- Instant results: Temperature readings are obtained quickly and provide immediate feedback.

- Versatility: Infrared thermometers have a wide range of applications in healthcare, industry, HVAC, and more.

- Ease of use: They are user-friendly and require minimal training.

- Safety: Infrared thermometers allow temperature measurement from a distance, ensuring safety in hazardous or hard-to-reach areas.

Cons of Infrared Thermometers:

- Surface measurement: They measure the temperature of the surface of an object and may not accurately represent the internal temperature.

- Environmental factors: Factors such as ambient temperature, humidity, and air movement can affect accuracy.

- Reflective surfaces: Infrared thermometers may struggle to provide accurate readings on shiny or reflective surfaces.

What is the main drawback of infrared technology?

The main drawback of infrared technology is its limitation in measuring the internal temperature of objects. Infrared thermometers only capture the thermal radiation emitted from the surface of an object, which may not reflect the true internal temperature. This limitation makes them less suitable for applications where precise internal temperature measurement is required, such as certain medical procedures or monitoring delicate electronic components. In such cases, alternative methods like invasive probes or contact temperature sensors may be necessary.

How does an infrared thermometer work?

An infrared thermometer works by detecting the infrared energy emitted by an object and converting it into a temperature reading. The device uses a lens to focus the infrared radiation onto a sensor, which then translates the energy into an electrical signal, providing the temperature reading on the display.

How to check the accuracy of an infrared thermometer?

To check the accuracy of an infrared thermometer, you can use a reference standard with a known temperature (e.g., an ice-water bath or boiling water). Compare the infrared thermometer’s readings with the known temperature to determine its accuracy.

How accurate is an infrared thermometer?

The accuracy of an infrared thermometer can vary, but most consumer-grade models have an accuracy of around ±1 to ±2 degrees Celsius (±2 to ±4 degrees Fahrenheit). Higher-end professional models may offer even greater accuracy, often within ±0.5 degrees Celsius (±1 degree Fahrenheit).

Related Articles:

- How Does a Thermal Imaging Camera Work?

- Choosing an Infrared Pyrometer

- A Guide to Industrial Sensors

- Can a Thermal Camera See Through Walls?

- How Does an Infrared Thermometer Work?

- 5 Best Infrared Thermometers

- Why is a Pin Sharp Thermal Image Important?

- How Can a Thermal Imaging Camera Become Part of Your Process?

- Can You Improve Your Thermal Efficiency With Imaging Cameras?

- Comparing Contact and Non-Contact Temperature Sensors

- What Is A Temperature Sensor?

- What is an Infrared Thermometer?

- How to Use an Infrared Thermometer

- Top Infrared Temperature Sensor Manufacturers

- What is a Pyrometer?