What Is An Infrared Thermometer? How Do They Work?

What Is An Infrared Thermometer?

What is an infrared thermometer? An infrared (IR) thermometer is a type of non-contact temperature sensor which measures the temperature of an object by detecting the heat energy, also known as infrared, emitted from the object.

This article aims to provide a comprehensive understanding of infrared thermometers, including:

- How infrared thermometers work

- The components of an infrared thermometer

- Advantages of infrared thermometers

- Common applications of infrared sensors

- Proper usage, limitations, and maintenance of IR sensors

How Does an Infrared Thermometer Work?

As an object’s temperature increases, it emits more infrared radiation. This radiation falls within the infrared range of the electromagnetic spectrum, which is invisible to the human eye.

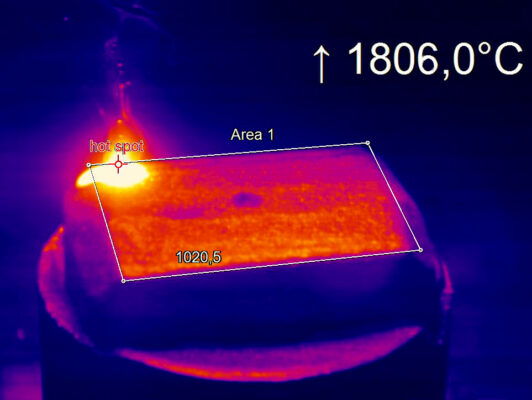

IR thermometers can detect and measure infrared radiation, the levels of which indicate how hot or cold an object is. They are typically used in hazardous environments, such as high-temperature or dangerous applications, due to not needing to come into contact with the object being measured.

Components of Infrared Thermometers

Infrared thermometers consist of several essential components. The optics, such as lenses, focus the infrared radiation emitted by the object onto an infrared sensor. The sensor, often made of thermopiles or pyroelectric materials, converts the detected radiation into an electrical signal.

A signal processor amplifies the signal, performs necessary calculations, and presents the temperature reading on the device’s digital display. Some IR sensors may include additional features, such as adjustable emissivity settings, memory for storing readings, or laser pointers to aid with precise aiming.

We are the leading UK distributor for Optris, a German manufacturer, of infrared thermometers and thermal imaging cameras used by our clients for applications such as metals, plastics and glass.

Contact our team to discuss your needs and find out how a non-contact temperature sensor can improve your process.

Contact UsGeneral Purpose IR Thermometers

General Purpose IR Thermometers

General Purpose IR Thermometers

What Are Infrared Thermometers Used For? Industrial Applications

Infrared thermometers find widespread use in various industrial applications due to their non-contact nature and ability to measure temperature quickly and accurately. Here are some examples of industrial applications for infrared temperature sensors:

- Industrial Maintenance and Troubleshooting: Identifying overheating components, detecting hotspots in electrical panels or machinery, and preventive maintenance for equipment failures or malfunctions.

- Product Manufacturing and Quality Control: Monitoring temperatures during manufacturing, curing or drying processes to ensure consistent temperature profiles and product quality.

- Energy Audits and Insulation Inspection: Identifying areas of heat loss or inefficient insulation, detecting thermal leaks, insulation gaps, or poorly sealed areas, allowing for targeted improvements to enhance energy efficiency.

- HVAC (Heating, Ventilation, and Air Conditioning): measuring temperatures in air ducts, vents, and HVAC system components, assisting with diagnostics, performance optimisation, and balancing airflows to ensure efficient heating or cooling.

- Automotive Industry: Measuring temperatures of engine components, exhaust systems, brakes, tires, and other automotive parts to identify potential issues, monitor performance, and assist in quality control.

- Research and Development: Assisting in temperature monitoring in laboratories during experiments, material identification and optimising processes.

Advantages of Using an Infrared Thermometer

Compared to traditional contact thermometers, infrared sensors offer several advantages. Non-contact measurement eliminates the need for physical contact, ensuring safety and minimising the risk of cross-contamination.

Infrared thermometers provide quick temperature readings, making them efficient for high-volume applications. Their convenience, accuracy, and suitability for various surfaces and objects make them versatile tools.

Benefits in Industrial Applications:

- Non-contact operation

- Speed

- Safety

- Versatility

- Non-destructive testing

- Remote monitoring capabilities

- Cost-effective

- User-friendly

Disadvantages of Using an Infrared Thermometer

While infrared thermometers offer numerous advantages, they also have limitations. Factors such as emissivity, which refers to the surface’s ability to emit radiation, can affect accuracy.

Reflective surfaces, excessive dust, ambient temperatures, and certain environmental conditions may introduce errors. Users must understand these limitations and consider the specific requirements of their application.

Infrared Thermometer Usage, Maintenance and Best Practices

Wondering “what is an infrared thermometer used for?” To ensure accurate readings, it is essential to use infrared thermometers correctly. Proper positioning, maintaining an appropriate distance from the target, and considering surface characteristics are crucial factors.

Environmental conditions, such as ambient temperature and humidity, can also impact measurement accuracy. Users must be aware of potential errors and take precautions to obtain reliable results.

Regular maintenance and calibration are essential for maintaining the accuracy of infrared thermometers. It is recommended to follow the manufacturer’s guidelines for cleaning, storage, and battery management. Periodic calibration ensures that the thermometer provides reliable temperature readings.

We offer a professional calibration service using our laboratory measurement equipment. Our team of highly trained experts are able to ensure that your temperature-measuring devices are performing correctly and conform to all manufacturer standards.

Contact UsWhat is an Infrared Thermometer? Final thoughts

Infrared thermometers are non-contact temperature sensors that detect infrared radiation emitted by objects, allowing for quick and accurate temperature measurement. Process Parameters, as the leading UK distributor for Optris, offers a range of infrared thermometers and other non-contact temperature sensors such as thermal imaging cameras.

These thermometers find extensive use in industrial applications such as maintenance, manufacturing, energy audits, HVAC systems, the automotive industry, and research. Their benefits include non-contact operation, speed, safety, versatility, non-destructive testing, remote monitoring capabilities, cost-effectiveness, and user-friendliness.

However, it is crucial to understand their limitations and follow best practices for accurate results.

Process Parameters also provides in-house calibration services to maintain the accuracy of temperature-measuring devices. By utilising infrared thermometers effectively and considering their limitations, industrial users can benefit from their efficiency and reliability in temperature measurement.

Send An EnquiryGeneral Purpose IR Thermometers

General Purpose IR Thermometers

General Purpose IR Thermometers

Infrared Thermometer FAQs

What is the difference between an infrared and probe thermometer?

An infrared thermometer measures temperature without direct contact by detecting the infrared radiation emitted by an object, while a probe thermometer requires physical contact with the object being measured. Infrared thermometers use non-contact methods and are ideal for industrial applications, offering speed, convenience, and safety, particularly for measuring moving objects or hazardous materials. Probe thermometers require direct contact and are commonly used in situations where physical contact is feasible and necessary for accurate temperature readings, such as in food preparation, medical settings, or laboratory experiments.

What is an infrared thermometer used for?

Infrared (IR) thermometers are used to quickly and accurately measure temperature without physical contact or touching the object being measured. They provide a convenient and efficient way to measure temperature from a distance, making them useful in various applications, ranging from industrial settings to everyday use in kitchens.

How does an infrared thermometer measure temperature?

An infrared thermometer measures temperature by detecting the thermal radiation (infrared energy) emitted by an object. It converts the intensity of this radiation into a temperature reading without making physical contact with the object, providing a non-invasive and quick temperature measurement.

Related Articles:

- How Does a Thermal Imaging Camera Work?

- How Accurate are Infrared Thermometers?

- Choosing an Infrared Pyrometer

- What is a Pyrometer?

- How to Use an Infrared Thermometer

- Why is a Pin Sharp Thermal Image Important?

- How Can a Thermal Imaging Camera Become Part of Your Process?

- Can You Improve Your Thermal Efficiency With Imaging Cameras?

- Comparing Contact and Non-Contact Temperature Sensors

- What Is A Temperature Sensor?

- Pyrometer or IR Camera?