How a Thermal Imaging Camera Can “See Through Walls”

Can Thermal Imaging See Through Walls?

In this article, we explain whether thermal imaging cameras can “see through” walls and other physical objects, as well as some common applications and how the technology works.

Thermal imaging cameras have become an invaluable tool for industrial processes by allowing maintenance teams, process engineers, and inspectors to visualise heat patterns behind walls, inside equipment, and beneath surfaces.

Have questions about implementing thermal technology into your business? Reach out to our team, or browse our industrial imaging cameras designed for even the most demanding environments.

Contact UsSo, can a thermal camera see through walls? Let’s find out.

Can Thermal Imaging Cameras See Through Walls?

No, thermal cameras cannot “see” through walls or concrete. However, if there is a hot or cold pipe within the wall, it’s likely a thermal camera will pick up on this.

Thermal cameras do not see through solid objects. Instead, they detect the subtle heat signatures that transmit from internal elements through barriers.

For example, concrete has low emissivity, meaning it does not efficiently emit the infrared radiation that thermal cameras capture. But, the heat from pipes, wires, ducts, and structural components radiates through the concrete to the surface.

The thermal camera picks up these heat patterns. Skilled thermographers then interpret the imaging to identify thermal irregularities that reveal leaks, blockages, breaks in insulation, or other issues.

Since the total depth a thermal camera can see depends on many factors, inspection teams normally use building plans that indicate element locations so that images provide the most accurate diagnostic insights.

What is a Thermal Imaging Camera?

Thermal cameras contain heat sensors that detect subtle temperature changes. The sensors translate these thermal readings into visible light to display detailed temperature data overlaid onto real images.

Advanced models allow spot temperature measurement, thermal video recording, image analysis tools, and software integration. When used with analytics, thermal data can quantify everything from process efficiency to building heat loss.

More information on thermal imaging cameras and how they work.

How Thermal Cameras Detect Heat Through Barriers

While the human eye sees visible light reflected off objects, thermal cameras detect the infrared radiation emitted by heat sources. This allows thermal cameras to “see” temperature variations through dust, fog, smoke, thin walls, glass, fabric, and even some metals.

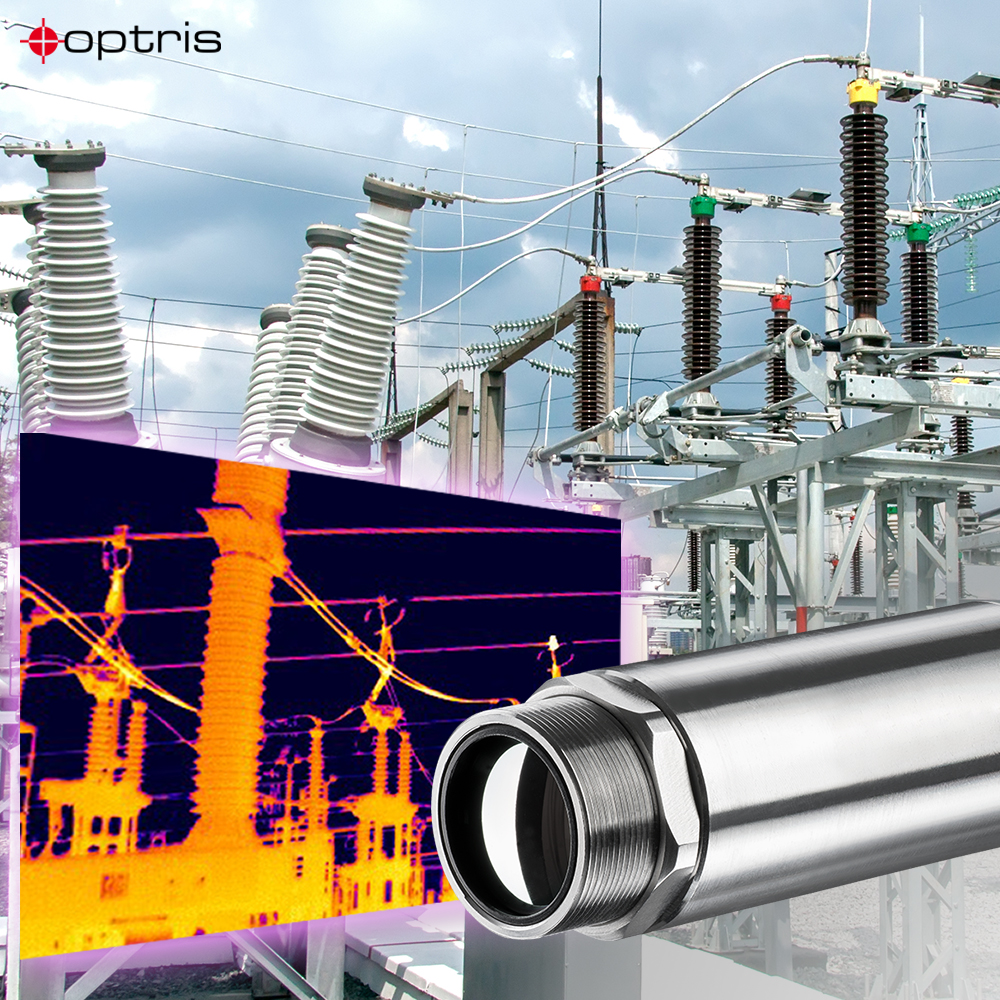

Rotating machinery, electrical faults, insulation gaps, and hundreds of other issues generate heat that thermal imagers can spot instantly, without needing to dismantle equipment or breach containment. This makes thermography invaluable for rapid inspections.

Using Thermal Imaging for Industrial Inspections

Inspectors use thermal imaging to rapidly survey facilities for temperature standard compliance, optimise equipment function, prevent downtime, and reduce operating expenses through energy efficiency and mitigating breakages.

By visualising heat, thermal cameras can provide unique insights for:

- Preventative maintenance: Scan mechanical parts, motors, pipes, tanks, and ducts for temperature changes indicating wear, blockages, leaks, or contamination

- Process monitoring: Check raw material quality, verify furnace/reactor conditions, reduce cycle times, and optimise set points by eliminating guesswork

- Facility Inspections: Scan piping insulation, equipment seals, cold storage, server rooms and other areas for maintenance oversight or energy audits.

- Product research and quality assurance: Heat distribution reveals defects and characterises how new product designs perform in real-world conditions

- Building diagnostics: Find missing insulation, air leaks, moisture damage and a wide range of other building envelope deficiencies by instantly visualising energy waste

At Process Parameters, we supply Optris thermal cameras which are renowned for their next-level thermography. From high temperature thermometers to thermal cameras for condition monitoring and early fire detection, we can help. If you’re looking for an infrared sensor for a specific use, contact our team today.

Send An EnquiryIndustrial Thermal Imaging Cameras

Industrial Thermal Imaging Cameras

Optris PI400i/PI450i High Resolution Thermal Imaging Cameras

Industrial Thermal Imaging Cameras

Industrial Thermal Imaging Cameras

What Are The Different Types of Thermal Screening and Scanning Devices?

Thermal scanners generate a real-time digital image of heat emitted from objects through the detection of infrared radiation. As well as built-in scanners, a wide range of portable thermal scanners have also been developed, with varying resolutions and price points.

For example, thermal scanners are currently available as handheld video cameras, handheld scopes, road vehicle and vessel-mounted scanners, as well as drone and manned aircraft-mounted cameras.

More information on thermal scanning.

Thermal Inspection Camera Options from Process Parameters

Process Parameters supplies innovative temperature measurement solutions tailored for industrial applications.

Whether you require reports to meet strict industry standards, or a simple spot infrared thermometer, let our thermal imaging specialists help select flexible, user-friendly systems to reduce downtime through predictive maintenance across your facility.

Contact our team to discuss your needs and find out how a thermal imaging camera can improve your process, or view our range of thermal cameras for a variety of industries.

Send us an email at sales@processparameters.co.uk, call 01628 778788, or complete our enquiry form.

Send An EnquiryGeneral Purpose IR Thermometers

General Purpose IR Thermometers

General Purpose IR Thermometers

Thermal Camera FAQs

How do thermal cameras see through solid objects?

Thermal cameras do not actually see through solid objects. They detect the unique infrared radiation signature that all objects emit proportional to their temperature. This allows thermal cameras to detect heat sources located behind barriers. Skilled thermographers use this imaging to locate and analyse issues.

What’s the difference between thermal vision and night vision?

Night vision uses electron amplification technology to increase visible light signals, allowing users to see conditions when little visible light is present. Thermal vision detects infrared radiation emitted from an object due to its temperature. Therefore, thermal cameras can visualise heat day or night, through light fog or smoke. Thermal imaging also quantifies temperatures while night vision offers more situational analysis.

Related Articles:

- How Does an Infrared Thermometer Work?

- How to Use an Infrared Thermometer

- What is Condition Monitoring?

- How Does a Thermal Imaging Camera Work?

- How Accurate are Infrared Thermometers?

- Using a Thermal Camera to Detect Heat Loss

- Choosing an Infrared Pyrometer

- What is a Pyrometer?

- What is Thermal Scanning?

- Why is a Pin Sharp Thermal Image Important?

- How Can a Thermal Imaging Camera Become Part of Your Process?

- Can You Improve Your Thermal Efficiency With Imaging Cameras?

- Pyrometer or IR Camera?