A Guide to Condition Monitoring

The Importance of Condition-Based Monitoring

Condition monitoring is a crucial aspect of maintenance and asset management, allowing organisations to proactively monitor the health of their equipment, detect anomalies, and prevent costly breakdowns.

In this guide, we will explore what condition monitoring is, why it is important, and how you can use thermal imaging cameras to make condition monitoring more efficient.

At Process Parameters, we offer a wide range of compact thermal imaging cameras which meet the requirements of almost all industries.

Send An EnquiryIndustrial Thermal Imaging Cameras

Industrial Thermal Imaging Cameras

Optris PI400i/PI450i High Resolution Thermal Imaging Cameras

Industrial Thermal Imaging Cameras

Industrial Thermal Imaging Cameras

What is Condition Monitoring?

Condition monitoring is the process of monitoring the condition of machinery, equipment, and assets in real time or at regular intervals to identify deviations from normal operating parameters.

It involves collecting data on various parameters such as vibration, temperature, acoustic emission, lubricant analysis, and thermography, and analysing this data to detect anomalies, irregularities, and machinery defects.

Every second machines are not working costs money. By monitoring equipment health, condition monitoring enables proactive maintenance, predictive maintenance, and preventive maintenance, reducing maintenance costs, downtime, and production loss.

The Importance of Monitoring Equipment

Condition monitoring plays a crucial role in equipment reliability, preventive maintenance, and cost savings.

By monitoring equipment parameters, vibration patterns, and machine health, condition monitoring helps detect abnormalities, irregularities, and deviations in machinery behaviour, alerting maintenance teams to potential defects, misalignment, lubricant degradation, leaks, imbalances, and breakdowns.

This proactive approach minimises machine failure, unplanned downtime, reactive maintenance, production loss, and costly repairs.

Condition monitoring also aids in monitoring equipment health, equipment reliability, and maintenance costs, contributing to plant productivity. It ensures that machinery defects are detected early, preventing costly breakdowns and reducing unplanned maintenance activities.

Industrial Use Cases in Manufacturing & Machinery

Industrial sectors find condition monitoring integral for various applications.

In manufacturing, it monitors machinery health, reduces production loss, and prevents costly downtime. The oil and gas industry relies on condition monitoring for equipment reliability, mechanical looseness, and corrosion monitoring.

Power generation benefits from condition monitoring for vibration monitoring, machinery diagnostics, and acoustic emission monitoring. The automotive sector utilises condition monitoring for monitoring equipment parameters, defect detection, and breakdown prevention.

Food and beverage industries use condition monitoring for vibration analysis, lubricant analysis, and ultrasonic monitoring. These diverse industrial applications demonstrate the significant role of condition monitoring in ensuring operational efficiency and preventing unexpected machinery failures.

What are the Different Types of Condition Monitoring Techniques?

There are several different types of condition monitoring techniques, including vibration analysis, thermography, oil analysis, ultrasound testing, and electrical monitoring.

Each technique has its unique advantages and is used to detect specific types of faults or abnormalities in machinery or equipment.

How Can Condition Monitoring Tools Save Money?

- Prolong the lifespan of machinery, motors, and systems

- Lower energy costs

- Decrease maintenance duration

- Enhance the efficiency of maintenance schedules

- Refine decisions regarding asset management

- Prevent unforeseen outages and unexpected downtimes

Benefits of Proactive Condition-Based Maintenance

Anticipating machine failures before they occur enables you to drive improvements that have positive ripple effects throughout the company, including:

1. Minimising Breakdowns, Downtime and Maximising Production

A significant portion of failures are not time-based. For many assets, failure can result in substantial or total production loss, often equating to significant financial impact.

While industries often prioritise larger, more expensive machines, it is essential to also focus on the smaller supporting machines. Prioritising the machines that generate revenue is important, but attention to the machines that enable the revenue-generating machines to function is equally crucial.

2. Enhancing Safety

Sole reliance on handheld devices for monitoring machine health can expose factory workers to unnecessary risks in highly automated factories.

Additionally, sporadic catastrophic breakdowns due to maintenance gaps can increase employee exposure to hazardous conditions and potential environmental disasters.

3. Reducing Maintenance Costs

While maintenance costs for individual assets may seem modest, when aggregated across numerous assets in manufacturing, these costs can be substantial.

Even a small reduction in maintenance costs for each asset through effective condition monitoring can significantly impact plant profitability.

Condition monitoring serves as a planning tool that provides valuable insights for planning and asset management, enabling proactive maintenance before functional failure occurs.

4. Mitigating Hidden Costs

Direct (traditional) maintenance costs are predictable and manageable, but indirect (hidden) maintenance costs can be up to five times higher.

Shifting from a reactive approach to a proactive, reliability-based approach is crucial for reducing these hidden costs, which are often steep and unnoticed.

5. Condition Monitoring Solutions

Condition monitoring solutions directly help prevent catastrophic machine breakdowns, which lead to costly downtime, production losses, safety concerns, and environmental impacts. Voiding these vulnerabilities is highly worthwhile.

Developing a successful programme with the right tools saves money in the long run.

Process Parameters provides a variety of handheld and stationary monitoring devices, all aimed at enhancing the efficiency of condition monitoring and assisting companies in optimising their uptime.

Our new Optris PI 640i CM is a pre-assembled product package for condition monitoring applications and early fire detection.

If you’re unsure about what you need for your application, contact our team who are happy to help find the best product for your needs.

View our range of thermal imaging cameras.

Predictive Condition-Based Maintenance

There are numerous methods for determining the timing of equipment maintenance:

- Allow the equipment to operate until it breaks down

- Implement routine maintenance regardless of the equipment’s condition

- Monitor the equipment to identify performance deterioration

Alternatively, take a proactive approach. Establish a cost-effective condition monitoring programme centred on thermal imaging and investigate the underlying reasons for equipment failure.

This approach will enable you to identify the ideal timing for maintenance and even enhance the equipment to prevent future failures, preventing company breakdowns.

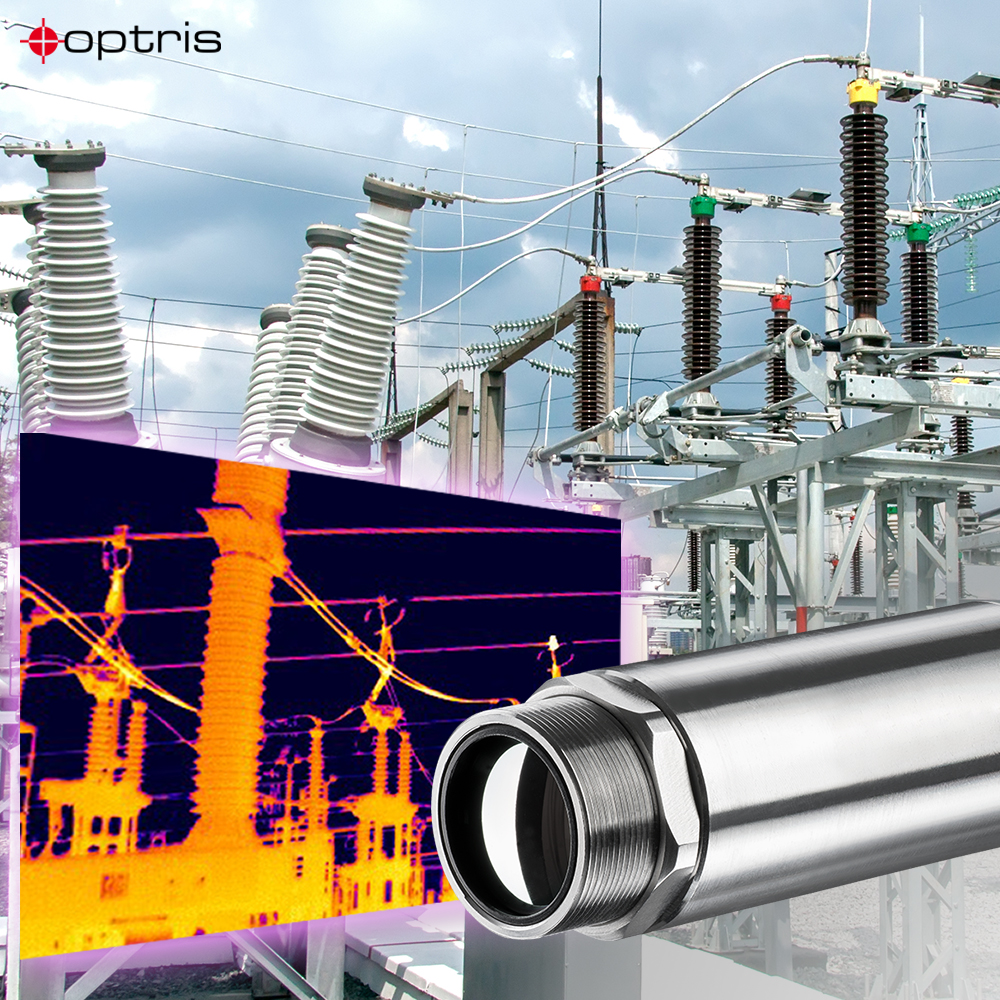

How Thermal Imaging Cameras Enhance Condition Monitoring

Thermal imaging cameras play a crucial role in enhancing condition monitoring. By detecting abnormalities and irregularities in equipment through data analysis, they enable the monitoring of machinery, bearings, and induction motors.

This helps in identifying deviations, imbalances, and anomalies, ultimately improving equipment reliability and preventing equipment failure. Integrating thermography into condition monitoring also allows for the detection of cavitation, leaks, and flaws.

Thermography Products for Condition Monitoring

Condition monitoring goes beyond mere equipment upkeep; it stands as a crucial responsibility ensuring the continuous flow of power, sustained machinery operation, prolonged equipment life, and the prevention of breakdowns for companies.

With advancements in technology, such as a thermal sensor, the capabilities of condition monitoring continue to expand. Embracing condition monitoring as a part of your maintenance strategy can lead to increased reliability, reduced repair costs, and overall operational excellence.

So, don’t wait any longer – start reaping the benefits of a condition monitoring system today.

Process Parameters provides a variety of handheld and stationary monitoring tools, along with inspection software, all crafted to enhance the efficiency of condition monitoring and assist companies in optimising their operational uptime.

Browse our thermal imagers and infrared thermometers for condition monitoring, or contact our experts for advice on which condition monitoring solution is best for your application.

Please send us an email at sales@processparameters.co.uk, call 01628 778788, or complete our online enquiry form.

Send An EnquiryIndustrial Thermal Imaging Cameras

Industrial Thermal Imaging Cameras

Optris PI400i/PI450i High Resolution Thermal Imaging Cameras

Industrial Thermal Imaging Cameras

Industrial Thermal Imaging Cameras

FAQs

Why should companies invest in condition monitoring?

Condition monitoring is important because it enables companies to proactively monitor the health of their equipment, identifying potential issues before they escalate into costly breakdowns or failures.

By continuously analysing data and monitoring key parameters, condition monitoring helps companies optimise equipment reliability, reduce repair costs, and minimise downtime. Investing in condition monitoring is a strategic move toward operational excellence and sustainable business growth.

How does condition monitoring improve equipment reliability?

Condition monitoring allows for real-time tracking of machinery performance, enabling early detection of deviations, imbalances, and anomalies. By identifying these issues promptly, maintenance teams can take.

How can condition monitoring improve the reliability of machines and equipment?

Condition monitoring is a vital practice that can improve the reliability of machines and equipment. By continuously monitoring the performance of machinery, it becomes easier to detect potential problems before they become major issues. This allows for timely maintenance and repairs, which can prevent costly breakdowns and downtime.

Additionally, condition monitoring helps to extend the lifespan of machines by identifying wear and tear and suggesting preventative measures. Properly implemented condition monitoring strategies can also increase safety in the workplace by reducing the risk of accidents caused by malfunctioning equipment.

What are the benefits of using wireless sensors for condition monitoring?

Wireless sensors are increasingly being used for condition monitoring in various industries. The benefits of using wireless sensors include reduced maintenance costs, improved asset reliability, and enhanced safety. Wireless sensors can detect and alert operators of any potential issues before they become serious problems, reducing downtime and repair costs.

They also eliminate the need for manual inspections, which can be dangerous in certain environments. Additionally, wireless sensors can provide real-time data that can be analysed to optimise equipment performance and reduce energy consumption.

Can condition monitoring help prevent unexpected downtime in manufacturing plants?

Yes, condition monitoring is an effective approach to prevent unexpected downtime in manufacturing plants. It involves regularly monitoring the performance and health of critical equipment and machinery to detect any potential issues before they escalate into major problems.

By using sensors and other monitoring tools, manufacturers can collect real-time data on the condition of their assets, enabling them to predict when maintenance or repairs are needed. This proactive approach can help reduce downtime, improve productivity, and save money on costly repairs and replacements.

Related Articles:

- How Does a Thermal Imaging Camera Work?

- Benefits of Industrial Inspection and Quality Control Cameras

- How Accurate are Infrared Thermometers?

- Can a Thermal Camera See Through Walls?

- How to Improve Manufacturing with an Industrial Camera

- How Does an Infrared Thermometer Work?

- Using a Thermal Camera to Detect Heat Loss

- What is Thermal Scanning?

- A Guide to Industrial Sensors

- Why is a Pin Sharp Thermal Image Important?

- How Can a Thermal Imaging Camera Become Part of Your Process?

- Can You Improve Your Thermal Efficiency With Imaging Cameras?