Industrial Cameras for Improved Manufacturing, Vision and Inspection

Industrial Camera for Manufacturing

In this article, we talk about when you would use a camera for manufacturing, specifically relating to industrial vision or machine vision systems.

In production and monitoring, leveraging the right technology can significantly enhance efficiency, quality, and safety. One important tool is the industrial camera, a cornerstone of modern industrial vision systems.

This article delves into the world of cameras for manufacturing, offering insights into their application, selection, and how temperature measurement is used in machine vision.

At Process Parameters, we specialise in providing cutting-edge temperature measurement devices and thermal cameras tailored to the unique needs of manufacturing companies in the UK.

Send An EnquiryWhat is an Industrial Camera?

Industrial vision, the application of computer vision to industrial settings, plays a pivotal role in automating and refining production processes.

Cameras for manufacturing are an essential part of machine vision. The types of cameras used can vary from monitoring cameras used for surveillance to machine vision cameras designed for integration into manufacturing processes.

These systems can detect objects or specific characteristics by capturing digital images through specialised cameras under optimal lighting conditions, facilitating quality control and process efficiency.

Industrial cameras capture and process image data for automatic inspections, ensuring products meet predefined quality standards.

The visual data gathered by the cameras is then processed using a computer, sometimes with artificial intelligence capabilities, to extract meaningful information.

Key Features of Industrial Cameras in Manufacturing

An industrial camera comprises a lens and a body, transforming light into digital data through an image sensor.

These sensors, capable of detecting a spectrum from visible light to X-rays, are crucial for various applications including process control, condition monitoring, robot guidance, and quality inspection.

When choosing an industrial camera for manufacturing, consider the application’s specific needs, including the type of object inspection and the environmental conditions.

Our team at Process Parameters offers expertise in selecting infrared cameras for temperature measurement, focusing on image quality, speed, and compatibility with existing systems, ensuring optimal performance and integration.

Contact Our TeamApplications of Machine Vision

Industrial cameras serve various sectors, from automotive and electronics to pharmaceuticals and food processing.

Their use in defect inspection, barcode reading, and automated quality control underscores their versatility and capability to enhance operational efficiency and product quality.

We offer expert guidance and high-quality solutions for your industrial process. Click here to see some of the industries that we supply.

Benefits of Industrial Vision in Manufacturing

Industrial vision systems offer numerous benefits for manufacturing processes. By automating quality inspections, they can significantly reduce waste and improve productivity.

Machine vision cameras can detect even minute defects rapidly and accurately, ensuring products meet quality control standards.

These systems also enable precise process adjustments, preventing issues before they arise.

Their analytical capabilities facilitate predictive maintenance of equipment as well. Industrial vision enhances manufacturing safety – advanced sensors can instantly detect anomalies.

Temperature Measurement in Manufacturing

Precise temperature measurement is vital for monitoring industrial processes and spotting irregularities.

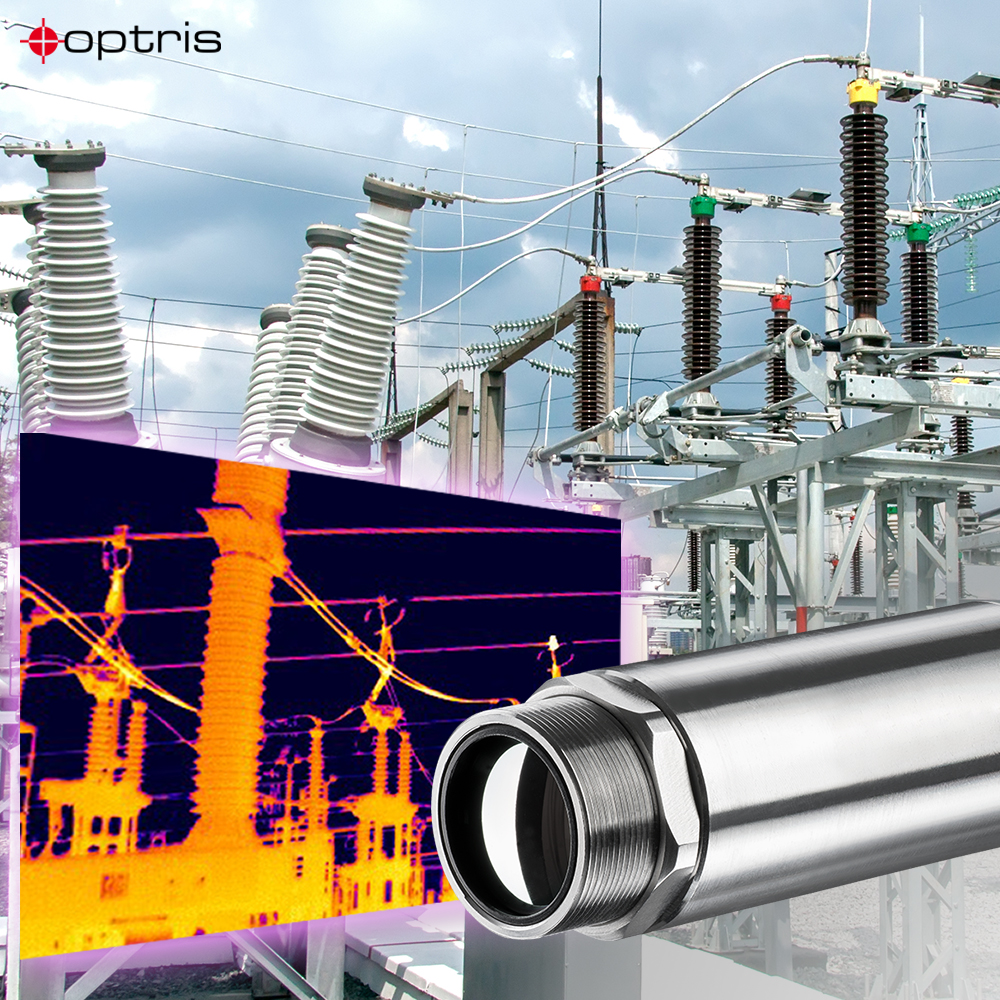

Thermal imaging cameras can non-invasively measure temperature changes in materials and equipment. Detecting hotspots facilitates predictive maintenance, reducing downtime.

Temperature data also enables fine-tuning heating/cooling equipment for energy efficiency. In metal processing, thermal profiling of furnaces mitigates product defects.

Food processing leverages thermal monitoring for product safety and quality control. Infrared thermography provides rapid, accurate temperature measurement for tighter process control.

- Optris Compact speciality cameras for the metal industry

- Optris CTlaser P7 infrared thermometer for thin plastic materials

How to Choose an Industrial Camera for Manufacturing

Several key considerations when selecting a camera for manufacturing include:

- Applications and inspection needs

- Environmental conditions (temperature, humidity, contamination)

- Required image resolution and sensor type (CCD, CMOS etc.)

- Lens mount support and lens characteristics

- Acquisition speed to match process velocities

- Interface (USB3, GigE etc.) for smooth data transfer

- Hardware and software integrations

- Robustness – housing, connectors etc. for reliability

- Budget

Getting the camera specifications right for your application ensures that the system delivers the expected benefits in automation, quality, efficiency and insights.

If you’re unsure about what you need for your application, contact our team who are happy to help find the best product for your needs.

View Thermal CamerasIndustrial Thermal Imaging Cameras

Optris PI Series Miniature Thermal Imaging Cameras

Optris PI400i/PI450i High Resolution Thermal Imaging Cameras

Optris Xi Compact Line Thermal Imaging Cameras

Industrial Thermal Imaging Cameras

Why Invest in an Industrial Camera for Manufacturing?

Implementing an industrial vision system requires upfront hardware and software investments.

While the benefits can be multi-fold in enhanced quality, efficiency, and insights, stakeholders often need convincing to sign off on significant camera and infrastructure spending.

However, there are numerous operational and fiscal benefits to the investment, such as:

- Productivity Improvements: Reduced inspection time leading to higher manufacturing throughput and capacity

- Scrap Reduction: Lower defect rates from automated quality processes enhancing yield

- Labour Cost Savings: Automating tedious visual tasks to redeploy workers on higher value activities or reducing headcount needs

- Maintenance Savings: Predictive capabilities lowering unexpected downtime expenses. Every second machines are not working costs money.

Maintenance savings in manufacturing can be huge. By monitoring equipment health, condition monitoring enables proactive maintenance, predictive maintenance, and preventive maintenance, reducing maintenance costs, downtime, and production loss.

For more information on how thermal imaging can enhance condition monitoring, read our in-depth guide.

How Can a Camera from Process Parameters Accelerate Productivity and Optimise Quality Control?

Industrial cameras are vital for automating inspection processes and enhancing quality control in manufacturing. These cameras are equipped with advanced features for high-resolution image capture, ensuring accurate and efficient process monitoring.

At Process Parameters, we understand the critical role that industrial cameras play in manufacturing success. Our range of temperature sensing and industrial vision solutions are designed to meet the highest standards of quality and reliability.

Whether you’re looking to reduce waste, ensure product quality, or optimise your manufacturing processes, our team is here to support you with tailored solutions.

Send us an email at sales@processparameters.co.uk, call 01628 778788, or complete our online enquiry form.

Send An EnquiryGeneral Purpose IR Thermometers

General Purpose IR Thermometers

General Purpose IR Thermometers

Camera for Manufacturing: FAQs

What is a machine vision camera?

Machine vision cameras are ‘the eyes’ of automatic imaging-based inspection and control. Applications include monitoring industrial processes, guiding robots, security monitoring, and medical imaging. The visual data gathered by the cameras is then processed using a computer, sometimes with artificial intelligence capabilities, to extract meaningful information.

What distinguishes an industrial camera from consumer models?

Industrial cameras deliver raw data with minimal latency, are designed for longevity, and offer superior image quality, especially in low-light conditions, making them essential for precise industrial applications.

Related Knowledge Guides:

- What is a Machine Vision Camera?

- What is Condition Monitoring?

- 5 Best Infrared Thermometers

- Industrial Sensors: A Comprehensive Guide

- Infrared Thermometer: How to Use for Enhanced Accuracy in Industrial Settings

- How Does a Thermal Imaging Camera Work?

- How Accurate are Infrared Thermometers?

- Can a Thermal Camera Detect Heat Loss?

- Choosing an Infrared Pyrometer

- What is a Pyrometer?

- What is Thermal Scanning?

- Why is a Pin Sharp Thermal Image Important?

- Can You Improve Energy Efficiency With Thermal Cameras?

- Pyrometer or IR Camera?