A Complete Guide to Infrared Thermometer Calibration

Industrial Infrared Thermometer Calibration

This guide covers how to calibrate an infrared thermometer, why it’s important, and recommendations for maintaining accuracy between calibrations.

Accurate temperature measurement is critical for product quality, operational efficiency, and safety in industrial facilities. Infrared thermometers provide non-contact temperature measurement but can lose accuracy over time due to ambient conditions, damage, and calibration drift.

Regular calibration traceable to national standards is essential for maintaining accuracy as well as protecting personnel and processes. So how do you do it?

The quick answer

Calibrating an infrared thermometer involves comparing its readings to a reference thermometer at two known temperature points: ice water (0°C/32°F) and boiling water (100°C/212°F). Adjust the infrared thermometer’s calibration settings to match the reference temperatures.

At Process Parameters, we offer a comprehensive in-house calibration service. For more information, or a free quote, please get in touch.

Contact usThe Comprehensive Guide to Infrared Thermometer Calibration

What is an Infrared/IR Thermometer?

An infrared thermometer is a non-contact device that measures temperature by detecting the infrared energy emitted by an object.

Unlike contact thermometers that require physical contact with the object, infrared thermometers can measure temperature from a distance. This makes them ideal for industrial applications where it’s impractical or unsafe to make direct contact with the object being measured.

More information on ‘What Is An Infrared Thermometer?’ from Process Parameters.

Why Is Infrared Thermometer Calibration Necessary?

Infrared thermometers are susceptible to various factors affecting accuracy, such as emissivity, distance, and ambient temperature.

- Emissivity is the ability of an object to emit infrared energy, and it varies depending on the material.

- Distance is the distance between the infrared thermometer and the object being measured.

- Ambient temperature is the temperature of the surrounding air.

Inaccurate temperature measurements can lead to product defects, safety hazards, and process inefficiencies in industrial applications. Regular calibration helps to ensure that infrared thermometers provide accurate and reliable temperature readings.

Our professional calibration service uses laboratory measurement equipment. Our team of highly trained experts ensure that your temperature-measuring devices are performing correctly and conform to all manufacturer standards.

How to Calibrate a Infrared Thermometer

To calibrate an infrared thermometer, you need to compare its readings to a reference thermometer at two known temperature points: 0°C/32°F for ice water and 100°C/212°F for boiling water. Then, adjust the calibration settings of the infrared thermometer to align with the reference temperatures.

Here are the steps for calibrating.

Equipment Needed

- Reference thermometer (probe or infrared) recently professionally calibrated

- Insulated container for ice water bath

- Heat-resistant container for boiling water bath

- Pure water (distilled or deionized)

- Crushed ice

- Heat source

- Calibration forms for recording data

Setting Fixed Distance

- Consult manufacturer instructions for distance specifications

- Use tape measure to measure and mark fixed distance for calibration

Calibration Temperature Points

- Compare IR thermometer against the reference thermometer in equilibrium at:

- Ice water bath (0°C /32°F)

- Boiling water bath (100°C/212°F)

If readings differ, adjust the IR thermometer according to manufacturer instructions to match the reference thermometer. Record adjustments made.

Ensuring Your IR Thermometer Stays Accurate

Infrared thermometers have gained popularity due to their non-contact functionality and user-friendliness. They offer precise temperature readings from a safe distance, eliminating the need for direct contact with the object or person being measured. However, factors such as distance to the target, ambient conditions, and surface properties can influence the accuracy of the reading.

To guarantee consistent industrial temperature measurement, it’s advisable to follow the manufacturer’s instructions and conduct regular calibrations.

How to Check the Accuracy of an Infrared Thermometer?

Test the infrared thermometer against known temperature standards, such as ice water and boiling water. Compare its readings to the reference temperatures to assess its accuracy.

More on Infrared Thermometer Accuracy from Process Parameters.

Tips for Maintaining Accuracy Between Calibrations

- Store the IR thermometer in a clean, dry, and dust-free environment.

- Clean the IR thermometer lens regularly to remove dirt or debris.

- Avoid exposing the IR thermometer to extreme temperatures or harsh environments.

- Follow the manufacturer’s recommendations for maintenance and storage.

Understanding Infrared Thermometer Calibration

Infrared thermometer calibration is the process of adjusting the thermometer’s settings to ensure that its readings match the actual temperature of the object being measured. Calibration is necessary because infrared thermometers are susceptible to various factors that can affect their accuracy.

Recommended Calibration Frequency

The frequency of calibration depends on the specific industrial application and the manufacturer’s recommendations. However, it is generally recommended to calibrate infrared thermometers at least once a year or more frequently if they are used in critical applications.

Accurate and Reliable Industrial Temperature Measurement

In industrial processes, accurate temperature measurement is essential for maintaining product quality, ensuring safety, and optimising process efficiency. Infrared thermometers, with their non-contact capabilities, have become indispensable tools for many of our customer’s applications.

However, their accuracy can be affected by emissivity, distance, and ambient temperature. Regular calibration is the key to maintaining precision, consistency and reliable temperature readings.

The calibration process, as outlined in this guide, involves comparing the infrared thermometer’s readings to a reference thermometer at two known temperature points: ice water and boiling water. This comparison allows for the adjustment of the infrared thermometer’s calibration settings to match the reference temperatures, ensuring accurate readings across a wide range of temperatures.

Regulatory Compliance for Industrial Temperature Measurement

Regulatory agencies, such as the Food and Drug Administration (FDA) and the International Organization for Standardization (ISO), have stringent guidelines for temperature measurement in industrial processes. These guidelines specify acceptable IR thermometer accuracy limits and calibration requirements to safeguard product quality, protect consumer safety, and maintain process integrity.

Regular calibration of infrared thermometers helps ensure that temperature readings adhere to these regulatory standards.

By maintaining the accuracy of these instruments, companies can:

- Demonstrate traceability to national standards: Regular calibration provides a traceable record of temperature measurements, linking them back to national standards. This traceability is crucial for regulatory compliance and quality assurance audits.

- Prevent product defects and safety hazards: Accurate temperature measurements are essential for preventing product defects and ensuring product safety. Inaccuracies in temperature readings can lead to product contamination, spoilage, or even safety hazards in certain industries.

- Optimise process efficiency and reduce waste: Precise temperature monitoring is crucial for optimising industrial processes and minimising waste. Inaccurate temperature readings can lead to inefficient energy consumption, process disruptions, and product waste.

Process Parameters: Your Trusted Calibration Partner

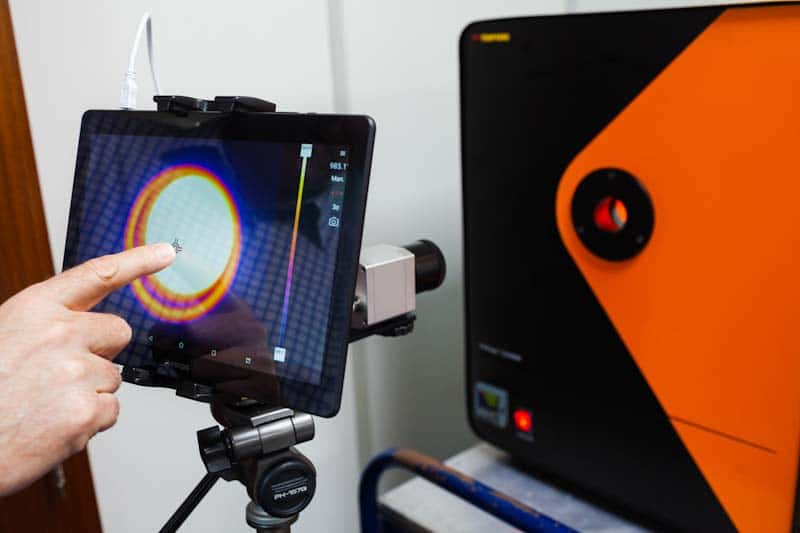

To ensure IR thermometer accuracy and reliability Process Parameters offers a comprehensive calibration service. Our experienced technicians will follow the manufacturer’s guidelines and use appropriate equipment to perform the calibration, providing consistent and reliable temperature readings for your industrial processes.

Contact Process Parameters today to schedule your infrared thermometer calibration service and safeguard the integrity of your industrial operations.

Please send us an email at sales@processparameters.co.uk, call 01628 778788, or complete our online enquiry form.

Contact us

IR Thermometer Calibration FAQs

How do I know if my infrared thermometer is accurate?

Compare the infrared thermometer’s readings to a reference thermometer or known temperature standards. Check the manufacturer’s specifications for acceptable accuracy limits.

How to check if the thermometer needs recalibration?

Compare IR thermometer readings to known temperature standards, such as ice water or boiling water, checking for inconsistencies or erratic readings. Monitor the thermometer’s performance over time and recalibrate if necessary.

How do you manually calibrate a thermometer?

Manual calibration involves using two reference temperature points, such as ice water and boiling water, to establish calibration points. Adjust the infrared thermometer’s settings to match the reference temperatures.

Can I calibrate my infrared thermometer myself?

Yes, infrared thermometer calibration can be performed by non-technical users following the manufacturer’s instructions and using the appropriate equipment. For highly critical applications or thermometers with complex calibration procedures, it is recommended to seek assistance from a qualified technician.

Related Articles:

- A Guide to Temperature Sensor Calibration

- How Does a Thermal Imaging Camera Work?

- How Accurate are Infrared Thermometers?

- Choosing an Infrared Pyrometer

- What is a Pyrometer?

- 5 Best Infrared Pyrometers

- Why is a Pin Sharp Thermal Image Important?

- How Can a Thermal Imaging Camera Become Part of Your Process?

- Can You Improve Your Thermal Efficiency With Imaging Cameras?

- Pyrometer or IR Camera?