Ensure Accurate Measurements: A Guide to Temperature Sensor Calibration

Calibrating a Temperature Sensor

Temperature sensor calibration guarantees the accuracy of temperature readings, a critical factor across countless industries.

From ensuring the safety and efficacy of pharmaceuticals to maintaining optimal food processing conditions, even minor deviations can have significant consequences.

Temperature precision can significantly impact product quality, safety, and regulatory compliance. Inaccurate measurements can lead to product spoilage, safety hazards, and costly production downtimes.

Introduction to Process Parameters

Process Parameters specialises in precision temperature measurement traceability solutions. We offer a wide range of calibration services tailored to meet the needs of diverse industries, ensuring the highest level of accuracy of your equipment and compliance with regulatory guidelines.

Email us at sales@processparameters.co.uk, call 01628 778788, or complete our online enquiry form.

Contact usUnderstanding Temperature Sensor Calibration

Temperature sensor calibration involves verifying and adjusting the output of a temperature sensor to ensure its readings match a known reference standard.

Who Needs Temperature Sensor Calibration?

A wide range of industries rely on temperature sensor calibration to maintain product integrity and adhere to strict regulatory standards.

- Pharmaceuticals: Ensuring consistent and accurate temperatures during drug manufacturing and storage is crucial for maintaining product quality and safety.

- Food & Beverage Production: Maintaining precise temperatures throughout processing is essential for food safety and preserving product quality.

- Manufacturing: Accurate temperature control is vital for various manufacturing processes, from plastics production to glass and metalworking.

- Energy & Utilities: Monitoring and controlling temperatures in power plants and other facilities is critical for efficient operation and safety.

- Research & Development: Precise temperature measurement is essential for scientific experiments and ensuring the validity of research data.

You may also like our guide to calibrating an infrared thermometer.

Types of Temperature Sensors

There are several types of temperature sensors, each with its own operating principle:

- Thermocouples generate a voltage based on temperature differences between two dissimilar metals.

- RTDs (Resistance Temperature Detectors) change resistance values in response to temperature variations.

- Thermistors exhibit a large change in resistance relative to a small change in temperature.

Each sensor type has its own accuracy specifications and limitations. Calibration helps ensure your sensors perform within their expected tolerances.

Thermocouple and RTD Calibration

Calibration of thermocouples and RTDs is imperative to confirm that temperature sensors and instruments are functioning optimally.

Unchecked equipment may lead to diminished process control, potentially escalating costs and compromising product quality. Regular recalibration is essential to maintain consistent performance and reliability.

Calibration of Temperature Probes

Regular calibration of temperature probes is essential to ensure they remain accurate.

The recommended frequency of the calibration will vary depending on the amount and manner in which a probe is used, the industry you are operating in, and the operational conditions. We can calibrate temperature probes at temperatures between -30°C to +240 °C.

- We calibrate Thermocouples, RTDs, Thermistors and Temperature Transmitters.

- We can measure all thermocouple types.

- All RTD types including Pt100 and Pt1000. 2, 3 or 4 wire. All standard resistance coefficients.

- Process signals including 4-20mA and voltages.

See our page on calibration for PT100 sensors.

Sensor Accuracy and Tolerance

Sensor accuracy refers to how close a sensor’s reading is to the actual temperature, while tolerance indicates the acceptable range of deviation from the true value3.

Factors Affecting Sensor Performance

Over time, several factors can affect sensor performance, including:

- Ageing: Sensors can naturally drift from their original calibration over time.

- Environmental conditions: Extreme temperatures, vibration, and exposure to harsh chemicals can degrade sensor performance.

- Physical damage: Dropping or mishandling a sensor can compromise its accuracy.

Regular calibration helps identify and address these issues before they significantly impact your readings.

Optimise Your Calibration Process with Our Expert Services

Discover the full suite of our calibration services and ensure your temperature sensors meet the highest standards of accuracy and performance.

Contact us to learn more and schedule your calibration today.

Contact usThe Temperature Sensor Calibration Process

Benefits of Regular Calibration (Improved Accuracy, Compliance, Safety)

- Improved Accuracy: Regular calibration ensures your sensors provide reliable and trustworthy temperature readings.

- Enhanced Compliance: Many industries have regulations requiring regular sensor calibration to maintain compliance standards.

- Increased Safety: Accurate temperature monitoring helps prevent accidents and product defects associated with incorrect temperature readings.

Pre-Calibration Considerations

Before sending your sensors for calibration, ensure they are clean and free of any damage. Provide any relevant documentation, such as sensor type, model number, and calibration history.

Calibrating Temperature Sensors

The specific calibration procedure can vary depending on the sensor type and service provider. However, it generally involves these steps:

- Comparison: The sensor’s output is compared against a highly accurate reference thermometer at various temperatures.

- Deviation Analysis: Any deviations between the sensor readings and the reference standard are identified.

- Adjustment (if necessary): Based on the analysis, adjustments are made to the sensor to ensure its readings align with the reference standard.

- Documentation: A calibration certificate is issued, detailing the performed procedures, reference standards used, and the sensor’s pre- and post-calibration readings.

Instruments For Calibrating a Temperature Sensor

The instrument used for calibration is a highly accurate reference thermometer. The specific type may vary depending on the required temperature range and desired level of accuracy. Some common reference thermometers include:

- Liquid-in-glass thermometers: For lower temperature ranges and applications requiring moderate accuracy.

- Dry-block calibrators: Electrically heated or cooled devices that provide a stable and uniform temperature environment for calibration.

- Thermocouple reference thermometers: Used for high-temperature applications.

- Resistance Temperature Detectors (RTDs) reference thermometers: Particularly suitable for calibrating RTD sensors.

The choice of reference thermometer ensures the overall accuracy and reliability of the calibration process for your temperature sensors.

Reference Standards Used in Calibration

Calibration service providers use reference thermometers with traceable calibrations to national standards like the International Temperature Scale of 1990 (ITS-90). This ensures the accuracy of your sensor calibration.

Typical Calibration Procedure

The specific calibration procedure may vary depending on the sensor type and service provider. Generally, it involves comparing the sensor readings against a reference standard at various temperatures. Adjustments are then made to the sensor if necessary.

Calibration Documentation and Certificates

There isn’t a single “standard” calibration for all temperature sensors.

The ideal approach depends on factors like:

- Sensor type (thermocouple, RTD, etc.)

- Required accuracy level

- Industry regulations

- Application requirements

However, common calibration standards include:

- UKAS Calibration: The most rigorous option, accredited by the United Kingdom Accreditation Service (UKAS).

- Traceable Calibration: Establishes an unbroken chain of documentation linking the calibration back to national temperature standards.

Upon completion, you will receive a calibration certificate detailing the performed procedures, reference standards used, and the sensor’s pre- and post-calibration readings. This documentation is crucial for maintaining traceability and demonstrating compliance with industry regulations.

Selecting the Right Calibration Service Provider

When choosing a calibration service provider, consider factors like:

- Experience and Expertise: Look for a company with a proven track record and extensive experience in calibrating your specific sensor types.

- Certifications: Ensure the provider maintains relevant accreditations and certifications traceable to national standards.

- In-situ vs. laboratory calibration.

Process Parameters emphasise these aspects in our temperature sensor calibration service.

We offer a traceable, UKAS-accredited calibration service, and our calibration is carried out in accordance with our quality management accreditation ISO9001:2015. This industry standard means all measurements are traceable back to National Standards.

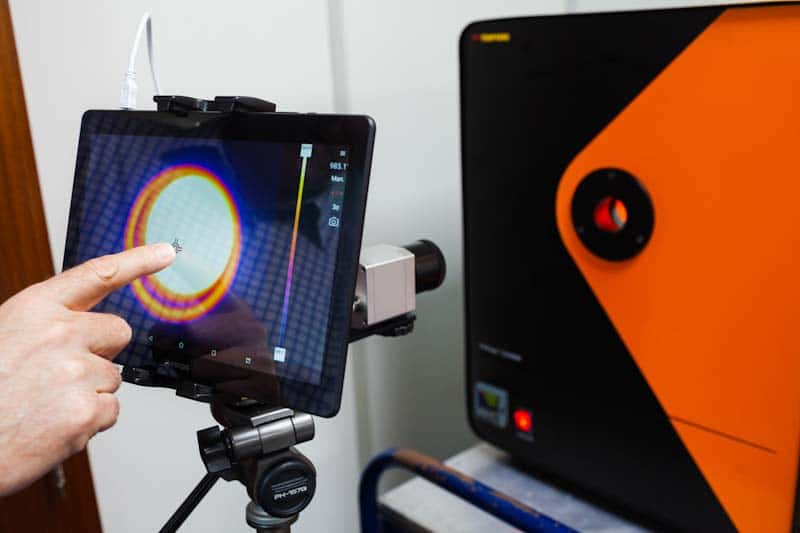

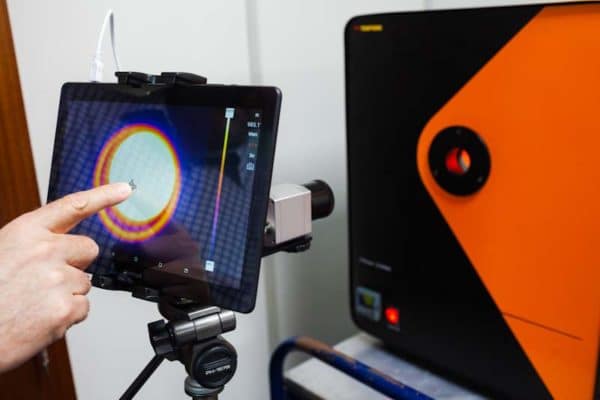

Contact usCalibration of Infrared Temperature Sensors

As an Optris Centre of Excellence, we have invested heavily in supporting the range of Optris infrared temperature sensors that we offer.

This not only includes our technical expertise with the product range but also enables us to calibrate many of the products in-house with our calibration facility.

- Black body temperature sources from ambient to 1200°C.

- Custom points – you choose the temperature we calibrate at.

- Independently calibrated reference pyrometers by German PTB.

- Optical geometry is carefully controlled during calibration to ensure utmost precision.

- Support a full range of outputs as required including mA, Voltage and thermocouple outputs. We can also support Optris USB interfaces and CompactConnect software directly.

- Calibrate other manufacturer’s infrared temperature sensors including Raytek, Land, Omega, Calex, DIAS and more.

Read our complete guide to infrared thermometer calibration for more information.

Advanced Topics in Temperature Sensor Calibration

Calibration Frequency Recommendations

The recommended calibration frequency depends on the sensor type, application, and environmental conditions. High-precision sensors used in critical processes may require more frequent calibration compared to those in less demanding applications.

In-situ vs. Laboratory Calibration

There are two main approaches to sensor calibration:

- In-Situ Calibration: Performed on-site without removing the sensor from its operating environment. This is suitable for sensors that are difficult or impractical to remove.

- Laboratory Calibration: Sensors are sent to a calibration lab for controlled testing under precise conditions. This method offers the highest level of accuracy.

Uncertainty Analysis in Calibration

Uncertainty analysis quantifies the doubt in the calibration results, providing a confidence level in the sensor’s accuracy.

Process Parameters, Your Temperature Sensor Calibration Partner

Regular temperature sensor calibration is indispensable for maintaining measurement accuracy and operational excellence.

With a dedication to precision, Process Parameters offers a comprehensive suite of calibration services catering to various sensor types and applications, state-of-the-art equipment, and custom solutions designed to meet specific client needs.

Contact Process Parameters for a Quote

For detailed information and a personalised quote, contact Process Parameters directly.

Email us at sales@processparameters.co.uk, call 01628 778788, or complete our online enquiry form.

Contact usCalibrating a Temperature Sensor: FAQs

What is the standard calibration of a temperature sensor?

There isn’t a single “standard calibration” for temperature sensors; it varies based on the sensor type and application requirements. Calibration is performed against reference standards traceable to national or international standards, ensuring measurement accuracy and traceability.

What instrument is usually used to calibrate a temperature sensor?

Instruments commonly used for temperature sensor calibration include dry-well calibrators, temperature baths, or temperature-controlled chambers. These instruments provide stable temperature conditions for accurate calibration. Additionally, reference thermometers with higher accuracy are often used alongside these instruments to ensure the calibration’s precision.