Pt100 Working Principle - What is a Pt100 Temperature Sensor?

Pt100 sensor working principle – A Pt100 is a sensor used to measure temperature. A PT100 temperature sensor is one type of sensor which falls into a group called Resistance Temperature Detectors or RTDs.

Before understanding how the sensor works, it is worth looking at some of the terminology used as this is extremely useful to know when identifying a sensor.

The sensor type, Pt100, indicates two important pieces of information about the sensor. The first part, Pt, is the chemical symbol for Platinum and this shows that the sensor is Platinum-based. The second part, 100, relates to the resistance of the device at 0°C. In this case 100Ω. There are a number of variations on this theme. There are other materials that can be used such as Nickel (Ni) and Copper (Cu) and different resistance values such as 50Ω, 500Ω and 1000Ω. This gives the possibility of sensors being identified as follows: Cu100, Ni120, Pt1000.

Platinum Resistance Thermometers (RTD Sensor, PRT, Pt100 Sensors, Pt1000)

Platinum Resistance Thermometers (RTD Sensor, PRT, Pt100 Sensors, Pt1000)

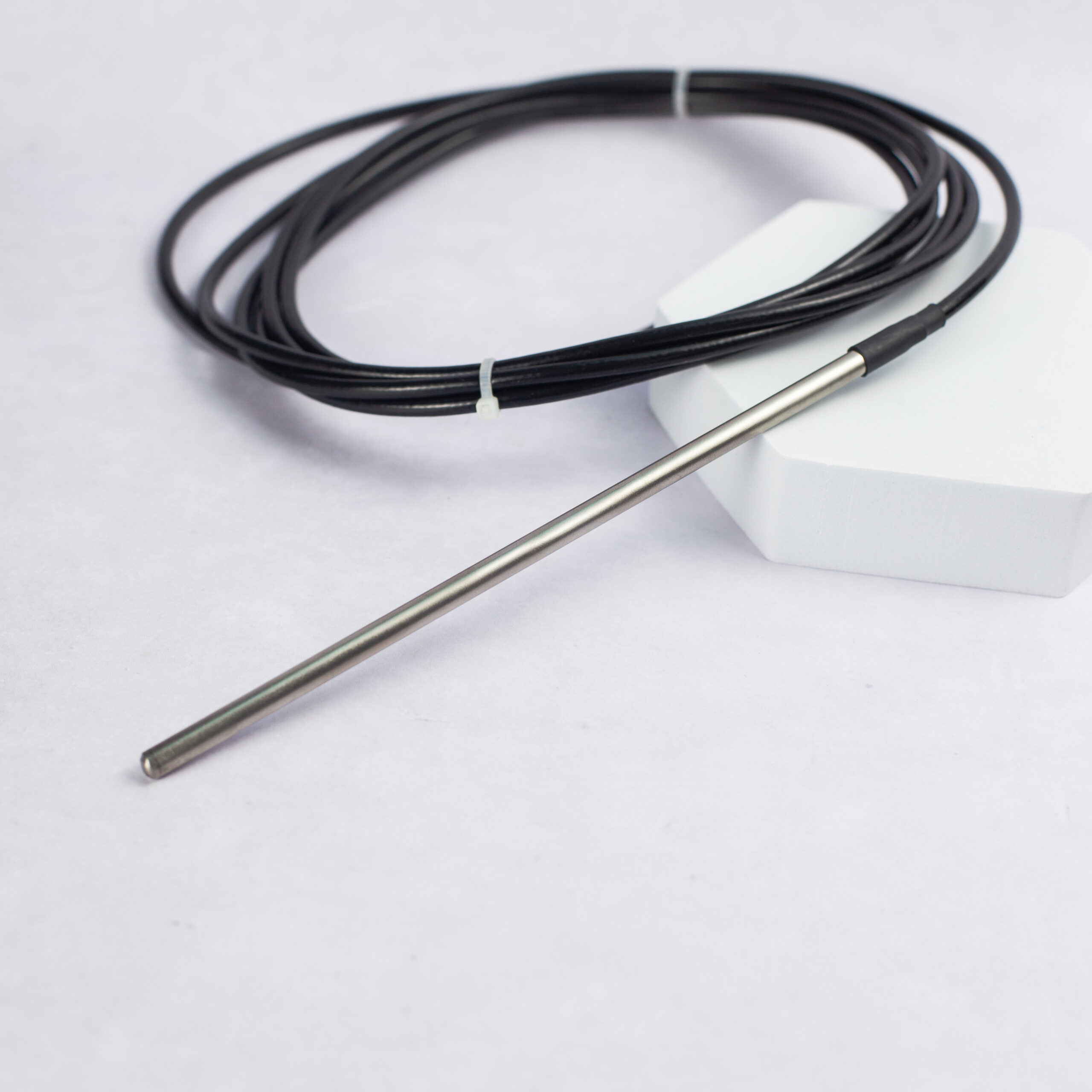

Industrial RTD Pt100 Temperature Sensor with KNE Terminal Head – PPL3 RTD Sensor

The Pt100 variant is however the most commonly used. Sensors using Platinum are also by far the most common group and are often referred to as Platinum Resistance Thermometers or PRTs.

As mentioned previously the Pt100 temperature sensor falls into a group of sensors called Resistance Temperature Detectors. The key word is “Resistance” because a Pt100 measures temperature by using a resistance change to denote the temperature value. For a Pt100, the resistance at 0°C is 100Ω and at 100°C, it is 138.5Ω. Therefore, the resistance change for each degree Celsius change is 0.385Ω.

This set of characteristics is set down in the relevant European and International Standards. In the UK we comply with BS EN 60751:2008 and this standard stipulates the resistance value, resistance change characteristics, tolerances and colour code for extension cables. All Pt100 temperature sensors manufactured by Process Parameters comply with this specification and are completely interchangeable with sensors from other manufacturers.

PT-100 sensor

by Process Parameters