A Guide to Common Industrial Temperature Measurement Devices

The Importance of Accurate Temperature Measurement in Industrial Processes

Accurate temperature measurement is crucial in industrial processes for maintaining quality, safety, and efficiency. Selecting the appropriate temperature measurement device can significantly impact process control, product quality, and operational costs.

In this guide, we discuss the different temperature measurement devices, and how to choose the right device for your application.

Process Parameters provides a wide range of temperature measurement solutions to meet the diverse needs of various industries.

Contact usHow to Select a Temperature Measurement Instrument

When selecting a temperature measurement device, consider the following factors:

- Temperature Range: Ensure the device can measure the expected temperature range of your application.

- Application: Different devices are suited to specific industrial processes and environments.

- Environment: Consider the operating conditions, including exposure to chemicals, humidity, and physical wear.

- Accuracy: Required precision can vary based on the application.

- Response Time: Some applications require faster response times than others.

- Cost: Budget constraints can influence the choice of device.

Types of Industrial Temperature Measurement Devices

Contact Temperature Measurement Devices

1. Thermocouples

Thermocouples are versatile sensors that generate a voltage based on the temperature difference between two dissimilar metals. They offer a wide temperature range and fast response time, making them suitable for applications such as:

- Furnaces and Kilns: Ideal for measuring extremely high temperatures.

- Exhaust Gas Measurement: Commonly used in automotive and industrial engines.

Advantages

- Wide temperature range

- Fast response time

- Durable and cost-effective

Disadvantages

- Requires proper installation

- Multiple wires can be cumbersome

2. Resistance Temperature Detectors (RTDs)

RTDs change their electrical resistance with temperature changes, offering excellent accuracy and stability over a wide range. They are ideal for:

- Chemical Processing: Ensuring precise temperature control.

- Pipelines: Monitoring fluid temperatures in various industrial applications.

Advantages

- High accuracy

- Stable and repeatable readings

- Suitable for a wide range of temperatures

Disadvantages

- Slower response time compared to thermocouples

- Higher cost

3. Thermistors

Thermistors exhibit a large change in resistance for a small temperature change, making them highly sensitive. They are suitable for:

- Temperature Compensation in Circuits: Ensuring accurate electronic readings.

- Low-Temperature Measurement: Ideal for medical devices and environmental monitoring.

Advantages

- High sensitivity

- Fast response time

- Cost-effective for specific temperature ranges

Disadvantages

- Narrow operating range

- Non-linear response

4. Bi-metallic Thermometers

These devices use a bimetallic strip that bends with temperature changes, commonly used for visual temperature monitoring in HVAC systems.

Advantages

- Simple and robust design

- Cost-effective

- Reliable in harsh environments

Disadvantages

- Limited accuracy

- Slow response

Non-Contact Temperature Measurement Devices

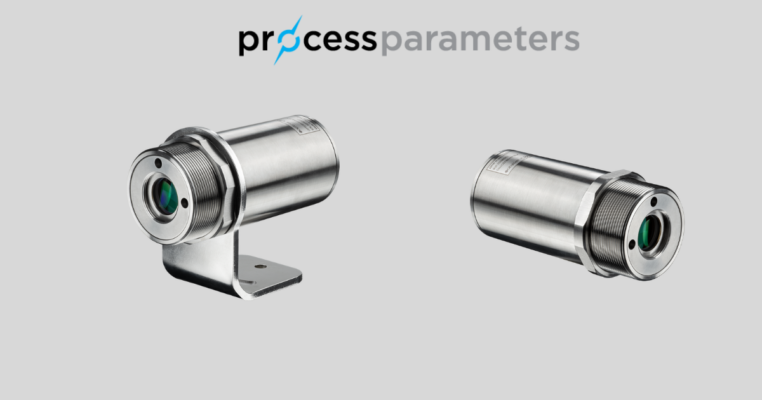

1. Infrared Thermometers (Pyrometers)

Infrared thermometers measure the infrared radiation emitted by an object to determine its temperature. They are ideal for:

- Surface Temperature Measurement: Suitable for moving objects.

- Hazardous Environments: Safe for high-temperature applications.

Advantages

- Non-contact measurement

- Fast response

- Safe for high-temperature or hazardous environments

Disadvantages

- Surface emissivity can affect accuracy

- Requires a clear line of sight

2. Radiation Pyrometers

Specialised for extremely high temperatures, radiation pyrometers measure the total thermal radiation emitted by an object, commonly used in:

Advantages

- Suitable for very high temperatures

- High accuracy

Disadvantages

- Often require special calibration for specific materials

- Higher cost

Selecting the Right Temperature Measurement Device

Choosing the right device requires careful consideration of your specific needs.

Compare devices based on temperature range, accuracy requirements, response time, application environment, and cost.

Consider sensor response time, immersion depth (for contact devices), and data logging capabilities.

Here’s a comparison table summarising key factors:

Feature | Thermocouple | RTD | Thermistor | Bi-metallic Thermometer | Infrared Thermometer | Radiation Pyrometer |

Temperature Range | Widest | Wide | Narrow | Limited | Wide | Highest |

Accuracy | Good | Excellent | High | Limited | Moderate | High |

Response Time | Fast | Slow | Fastest | Slow | Fast | Moderate |

Application Environment | Industrial | Industrial | Electronics | General Purpose | Industrial, Hazardous | Industrial, High Temp |

Cost | Moderate | High | Moderate | Low | Moderate | High |

Maintaining Temperature Measurement Accuracy

Regular calibration of temperature sensors is essential for ensuring reliable readings over time. Uncalibrated sensors can lead to inaccurate process control, impacting quality and increasing costs.

Process Parameters offers UKAS-accredited calibration services for various sensor types.

Contact us to learn more and schedule your calibration today.

Contact usProcess Parameters: Your Partner in Precision

Selecting the appropriate temperature measurement device is crucial for ensuring optimal performance in your industrial processes.

Process Parameters is a leading provider of top-quality temperature measurement devices and services. We are committed to exceeding your expectations with:

- Custom Solutions for Industry-Specific Needs: Our team can design and manufacture custom temperature measurement devices to meet your specific requirements.

- State-of-the-Art Equipment: We utilise the latest advancements in temperature measurement technology to ensure the highest levels of accuracy and reliability.

For more information or to request a quote, contact Process Parameters today. Our experts are ready to help you find the perfect temperature measurement solution for your specific industrial application.

Email us at sales@processparameters.co.uk, call 01628 778788, or complete our online enquiry form.

Send an EnquiryFAQs

What are temperature measurement devices?

Temperature measurement devices are tools that detect and record temperature. They range from simple thermometers to complex thermal imaging cameras. These devices are used in many applications, from checking your fever to monitoring industrial processes.

What factors should I consider when choosing a temperature measurement device?

Consider the temperature range, application, environment, accuracy requirements, response time, and cost.

Why is regular calibration important for temperature sensors?

Calibration ensures that the temperature readings are accurate and reliable, which is critical for process control and safety.

Related Articles:

- What is a Thermocouple?

- What is a Temperature Transmitter?

- Comparing Contact and Non-Contact Temperature Sensors

- What Is A Temperature Sensor?

- How Do Thermal Imaging Cameras Work?

- 5 Benefits & Applications of Thermal Imaging Cameras

- 5 Best Infrared Thermometers

- What is an RTD?

- What is a Thermometer?

- A Guide to Infrared Sensor Calibration

- How to Calibrate Pt100 Sensors and Temperature Probes

- Guide to Temperature Sensors For Glass Melting Furnaces