The Advantages and Disadvantages of Thermocouples

Advantages and Disadvantages of Thermocouple Sensors

Thermocouples are essential temperature sensors widely used in science and industry. One of the main advantages of thermocouples is that they can be made to suit almost any application.

They can be made to be robust, fast responding and to measure a very wide temperature range. However, they also come with limitations.

This article delves into the advantages and disadvantages of thermocouples, aiding professionals in making informed decisions for their specific application requirements.

Process Parameters is a leading supplier of temperature sensors, including thermocouples, in the UK. We offer comprehensive solutions for various temperature measurement needs, backed by a commitment to quality and customer service.

Contact usHow Does a Thermocouple Work?

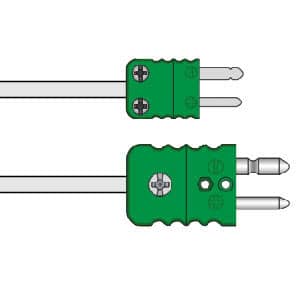

Thermocouples are fundamental temperature sensors widely utilised in both scientific and industrial applications. These devices consist of two wires made from different metals, joined at a single junction, which is typically welded for enhanced durability and reliability.

At the open ends of these wires, a thermocouple generates a voltage in response to the junction temperature.

Read our comprehensive guide for more information: What is a Thermocouple?

Types of Thermocouples

Any two dissimilar metal wires in contact will produce a voltage when heated. However, certain alloy combinations are standardised due to their output levels, stability, and chemical properties.

- Base Metal Thermocouples: Made with iron or nickel alloys, classified as Types J, K, T, E, and N.

- Noble Metal Thermocouples: Made of platinum-rhodium and platinum wires for higher temperature applications, known as Types R, S, and B.

Depending on the type, thermocouples can measure temperatures ranging from about -270°C to over 1,700°C (approximately -454°F to over 3,100°F).

Read our guide to thermocouple types and thermocouple temperature ranges for more information.

To get an idea of the typical designs available check out some of our thermocouple sensors.

Thermocouple Sensors for Industrial Applications

Temperature Probes & Sensors

Thermocouple Sensors for Industrial Applications

Thermocouple for Ambient Air Temperature Measurement Sensor – PPL10-T

Temperature Probes & Sensors

Thermocouples: Weighing the Advantages and Disadvantages

Due to their simplicity and effectiveness, thermocouples have become a staple in temperature measurement and control.

However, understanding the limitations of thermocouples is crucial for their effective use.

Limitations of Thermocouples

The voltage output of a thermocouple is very small, typically around 0.001 volts at room temperature, increasing with temperature.

Each thermocouple type has a specific equation to convert voltage to temperature, which is not linear and can be quite complex. Despite this, thermocouples generally offer accuracy to about 1°C (2°F) at best.

To obtain calibrated results, the thermocouple voltage must be compared to a reference value. Traditionally, this involved another thermocouple in an ice-water bath, creating a “cold junction” at 0°C (32°F). Modern electronic ice-point reference circuits have replaced this method, making thermocouples more convenient for portable applications.

Thermocouples are also susceptible to corrosion, which can impact their calibration and accuracy. In harsh environments, the junction is often protected by a steel sheath to prevent moisture or chemicals from damaging the wires. Regular care and maintenance are necessary to ensure long-term performance.

Applications of Thermocouples

The benefits of thermocouples have led to their use in a variety of applications, from controlling household ovens to monitoring temperatures in aircraft, spacecraft, and satellites. They are also used in kilns, autoclaves, presses, and moulds in manufacturing processes.

Multiple thermocouples can be connected in series to form a thermopile, which generates a higher voltage in response to temperature changes than a single thermocouple.

Thermopiles are used in sensitive devices for detecting infrared radiation and can also generate power for space probes through the heat of radioactive decay in a radioisotope thermoelectric generator.

By understanding the advantages and limitations of thermocouples, professionals can make informed decisions for their specific applications, ensuring reliable and accurate temperature measurements.

Advantages and Disadvantages of Thermocouples

Advantages of Thermocouples | Disadvantages of Thermocouples |

Wide Temperature Range | Accuracy |

Can measure a vast range of temperatures, from cryogenic levels to extremely high temperatures. | Requires careful handling and regular calibration to maintain accuracy; generally less precise than some other sensors. |

Versatility | Reference Junction Dependence |

Available in various types (e.g., Type K, J, T, E, N, R, S, B), catering to specific needs and environments. | Accuracy is influenced by the reference junction temperature, which must be monitored and compensated for. |

Low Cost | Susceptibility to Electrical Noise |

Generally more affordable compared to other temperature sensors. | Measurements can be affected by electrical interference, necessitating proper shielding and grounding. |

Simple Design | Limited Chemical Resistance |

Basic construction, typically involving just two wires, makes them easy to use and maintain. | Some thermocouple materials are prone to corrosion, limiting use in chemically aggressive environments. |

Fast Response Time | Installation Considerations |

Certain types can quickly respond to temperature changes, crucial in dynamic processes. | Proper installation is critical for reliable performance; incorrect installation can lead to errors and reduced lifespan. |

Durability | Low Voltage Output |

Robust and can withstand harsh environments when protected by appropriate sheaths. | The small voltage output requires amplification and careful electronic design, making the system more complex. |

Portability | Noise and Interference |

Modern electronic ice-point reference circuits enable portable applications. | Low voltage response is susceptible to noise and interference, which may require grounded shielding. |

Choosing the Right Temperature Sensor

When selecting a temperature sensor, it’s essential to weigh the advantages and disadvantages of thermocouples against other options. Factors such as the specific application, operating environment, required accuracy, and budget should guide the decision-making process.

Process Parameters offers expertise in helping customers choose the right sensor for their needs, ensuring optimal performance and reliability.

We provide a comprehensive range of temperature sensors, including thermocouples. Our team is dedicated to assisting customers in selecting the best sensor based on their unique requirements. Contact us today for a quote or to discuss your temperature sensor needs.

Email us at sales@processparameters.co.uk, call 01628 778788, or complete our online enquiry form.

Send an EnquiryPlatinum Resistance Thermometers (RTD Sensor, PRT, Pt100 Sensors, Pt1000)

RTD Pt100 Temperature Sensor PPL3-P, IP68 KNE Terminal Head, 4-20mA Transmitter

Platinum Resistance Thermometers (RTD Sensor, PRT, Pt100 Sensors, Pt1000)

Platinum Resistance Thermometers (RTD Sensor, PRT, Pt100 Sensors, Pt1000)

Platinum Resistance Thermometers (RTD Sensor, PRT, Pt100 Sensors, Pt1000)

Thermocouple FAQs

What are the advantages of thermocouples?

- Wide Temperature Range: Can measure from cryogenic to extremely high temperatures.

- Versatility: Available in various types for different applications.

- Low Cost: More affordable than many other temperature sensors.

- Simple Design: Easy to use and maintain.

- Fast Response Time: Quickly responds to temperature changes.

- Durability: Can withstand harsh environments with proper protection.

- Portability: Suitable for portable applications.

What are the disadvantages of thermocouples?

- Accuracy: Requires regular calibration and handling care.

- Reference Junction Dependence: Needs temperature compensation at the reference junction.

- Electrical Noise: Susceptible to interference without proper shielding.

- Chemical Resistance: Some materials are prone to corrosion.

- Installation: Requires correct installation for reliable performance.

- Low Voltage Output: Needs amplification and careful electronic design.

- Noise and Interference: Can be affected by electrical noise, requiring grounded shielding.

Related Articles:

- What is a Thermocouple?

- What Is A Temperature Sensor?

- How Does a Thermocouple Work?

- How Accurate are Thermocouples?

- What Are Type K Thermocouples?

- Differences Between J and K Type Thermocouples

- RTD vs. Thermocouple: Choosing the Right Temperature Sensor

- Thermistors vs Thermocouples: Choosing the Right Sensor

- 5 Different Types of Thermal Sensors