RTD vs. Thermocouple: Choosing the Right Temperature Sensor for Your Application

What is the Difference Between an RTD and a Thermocouple?

Resistance temperature detector (RTD) vs. thermocouple: both widely-used temperature sensors, but what’s the difference? And why does it matter?

Temperature sensors ensure precise monitoring and control in temperature-dependent processes. Selecting the appropriate sensor is crucial for achieving accuracy and reliability in industrial processes, scientific experiments, and everyday applications.

Accurate and reliable temperature data is essential for process control, quality assurance, and safety. Two of the most common temperature sensors are resistance temperature detectors and thermocouples.

This article will help you understand the differences between RTDs and thermocouples and guide you in selecting the most suitable sensor for your needs.

We are a leading UK manufacturer of temperature reader and measurement solutions, offering a wide range of custom-built RTD and thermocouple temperature sensors for industrial applications.

If you would like advice or a free quote, please do not hesitate to contact the team at Process Parameters.

Contact Our TeamRTD vs. Thermocouple

Understanding RTD and Thermocouples

RTDs and thermocouples are two common types of temperature sensors, each with distinct operating principles and construction materials.

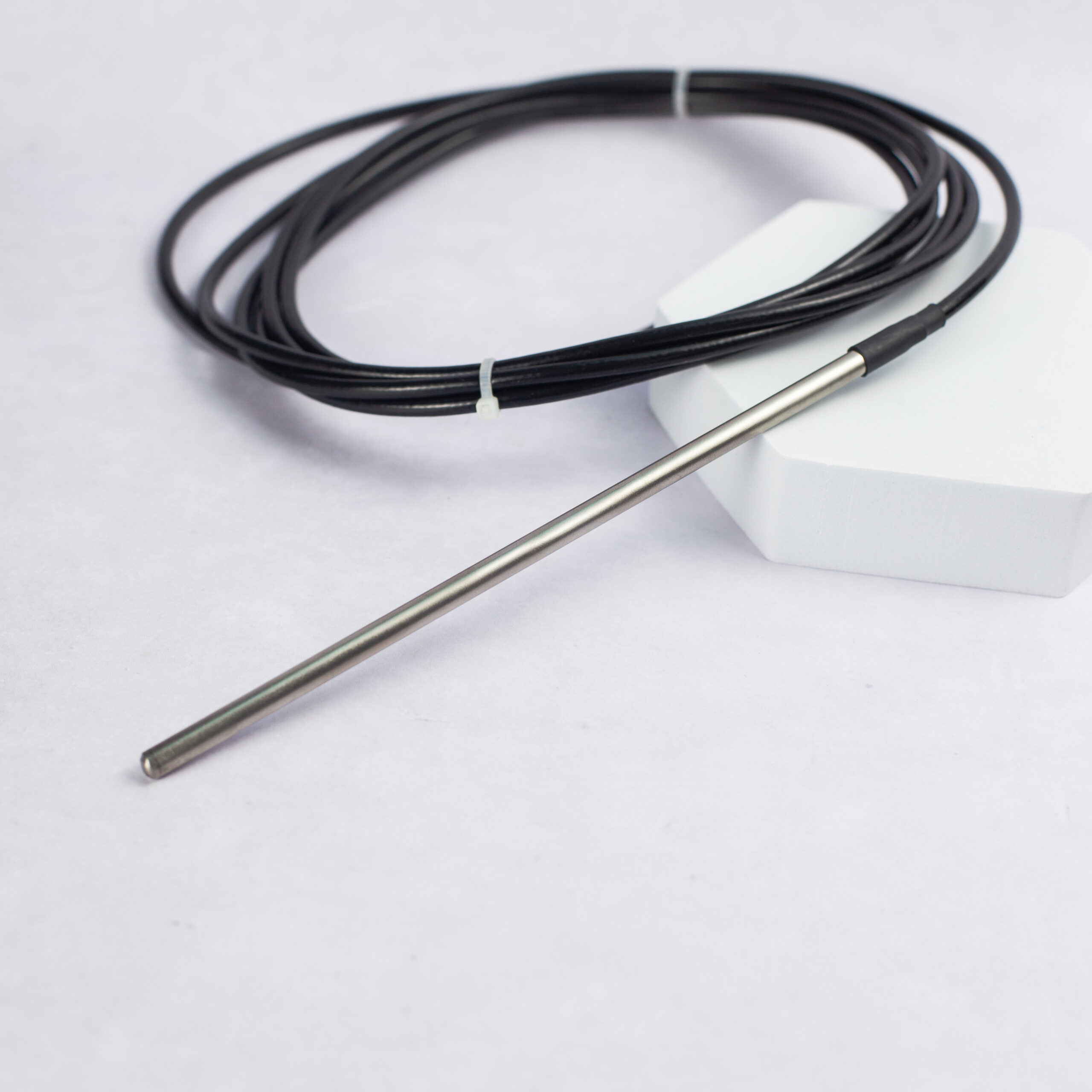

Resistance Temperature Detector (RTD)

An RTD detects temperature changes through variations in the resistance of its element (often platinum, copper, or nickel). As temperature rises, the resistance increases predictably, allowing for highly accurate temperature calculations.

Our RTD sensors are ideal for general-purpose industrial and OEM applications. We’re able to manufacture our resistance thermometers to your requirements for almost any environment.

Platinum Resistance Thermometers (RTD Sensor, PRT, Pt100 Sensors, Pt1000)

RTD Pt100 Temperature Sensor PPL3-P, IP68 KNE Terminal Head, 4-20mA Transmitter

Platinum Resistance Thermometers (RTD Sensor, PRT, Pt100 Sensors, Pt1000)

Platinum Resistance Thermometers (RTD Sensor, PRT, Pt100 Sensors, Pt1000)

Platinum Resistance Thermometers (RTD Sensor, PRT, Pt100 Sensors, Pt1000)

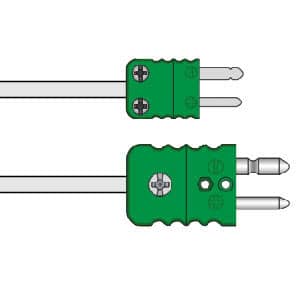

Thermocouple

Thermocouples rely on the Seebeck effect (also known as the thermoelectric effect), generating a voltage when exposed to a temperature gradient. The voltage produced is directly proportional to the temperature difference between measurement and reference junctions.

To get an idea of the typical design available check out some of our thermocouple sensors.

Thermocouple Sensors for Industrial Applications

Temperature Probes & Sensors

Thermocouple Sensors for Industrial Applications

Thermocouple for Ambient Air Temperature Measurement Sensor – PPL10-T

Temperature Probes & Sensors

For more information, read our in-depth guides:

RTD vs. Thermocouple: Main Differences

The differences between Thermocouples and RTDs are:

- Temperature range capabilities

- Accuracy and precision

- Response time and performance

- Wiring and installation

- Cost

- Application scenarios

We expand on all of these below.

Temperature Range Capabilities

RTDs typically have a more limited temperature range, suitable for temperatures ranging from -200°C to 850°C. In contrast, thermocouples can measure a broader temperature range, from -270°C to 2,300°C, depending on the type of metals used.

Accuracy and Precision

RTDs typically offer higher accuracy and stability due to their predictable resistance-temperature relationship and minimal drift over time.

Thermocouples, while generally less accurate, excel in harsh environments and high-temperature applications due to their rugged construction. Factors influencing accuracy include sensor calibration, stability, and environmental conditions.

Response Time and Performance

Thermocouples generally have a faster response time compared to RTDs, making them better suited for measuring rapidly changing temperatures. This is because thermocouples have a smaller thermal mass and can respond quickly to temperature changes.

Wiring and Installation

RTDs and thermocouples demand meticulous installation for accurate temperature readings. RTD wiring configurations include two, three, or four-wire setups, while Thermocouples require attention to extension wire selection to maintain accuracy.

Both RTDs and thermocouples must be carefully positioned and mounted during installation to ensure accurate temperature measurements. Proper immersion depth, thermal contact, and insulation from external influences are essential considerations for both sensor types.

Cost Comparison

While RTDs generally have higher initial costs than thermocouples, they may offer better long-term cost-effectiveness due to their superior accuracy and stability, resulting in fewer calibration and maintenance requirements over time.

Thermocouples are generally more economical upfront due to their simpler construction and fewer materials required. However, their long-term maintenance costs may be higher due to their shorter lifespan and potential for drift or degradation over time, necessitating more frequent replacement or recalibration.

Application Scenarios

RTDs are commonly used in applications where high accuracy and stability over a narrow temperature range are essential, such as in laboratory environments, pharmaceutical manufacturing, precision instrumentation, and HVAC systems where temperature control is critical.

Thermocouples excel in high-temperature environments and applications where rapid temperature changes must be measured.

They are widely used in industrial processes like furnaces, kilns, industrial ovens, metal smelting, glass manufacturing, exhaust gas monitoring, and automotive and aerospace applications where fast response times are necessary.

Which is Better: RTD or Thermocouple?

The choice between an RTD and a thermocouple depends on various factors, including temperature range, accuracy requirements, response time, cost considerations, and environmental conditions.

If the application requires measuring temperatures beyond the capabilities of RTDs (typically above 850°C), thermocouples are the better choice. However, if high accuracy and stability are crucial, especially over a narrow temperature range, RTDs offer superior performance.

If rapid temperature changes need to be measured, thermocouples are preferred due to their faster response time. Regarding cost and maintenance, RTDs may have a higher initial cost but lower maintenance costs over their lifetime, while thermocouples are more economical upfront but may require more frequent replacement or recalibration.

Use case examples of RTDs vs. Thermocouples

In a pharmaceutical manufacturing facility, where precise temperature control is essential for product quality and safety, RTDs are commonly used due to their high accuracy and stability.

In a steel foundry, where temperatures can reach up to 1800°C, thermocouples are the preferred choice because of their ability to withstand extreme temperatures and their faster response times.

In an automotive engine testing laboratory, where rapid temperature changes need to be measured accurately, a combination of RTDs and thermocouples may be employed, with RTDs providing high accuracy for steady-state measurements and thermocouples capturing transient temperature changes.

Conclusion

Both RTDs and thermocouples come with strengths and weaknesses. Understanding their differences and considering your specific application requirements are crucial steps in selecting the most suitable temperature probe for accurate temperature measurement and control.

At Process Parameters, we offer a wide range of high-accuracy sensors for industrial applications. From sensors for high temperatures to fast response and strong stability, we can help.

Email us at sales@processparameters.co.uk, call 01628 778788, or complete our online enquiry form.

Send An EnquiryPlatinum Resistance Thermometers (RTD Sensor, PRT, Pt100 Sensors, Pt1000)

RTD Pt100 Temperature Sensor PPL3-P, IP68 KNE Terminal Head, 4-20mA Transmitter

Platinum Resistance Thermometers (RTD Sensor, PRT, Pt100 Sensors, Pt1000)

Platinum Resistance Thermometers (RTD Sensor, PRT, Pt100 Sensors, Pt1000)

Platinum Resistance Thermometers (RTD Sensor, PRT, Pt100 Sensors, Pt1000)

RTD vs. Thermocouple Frequently Asked Questions

What is the main difference between RTD and thermocouples?

RTDs rely on changes in electrical resistance for temperature measurement, while Thermocouples generate a voltage proportional to temperature differences between dissimilar metal junctions.

Why is RTD more accurate than thermocouples?

RTDs are generally more accurate than thermocouples because the resistance-temperature relationship of the RTD element is well-defined and can be precisely calibrated. Additionally, RTDs exhibit excellent long-term stability and repeatability, ensuring consistent and reliable measurements over time.

Why use RTD instead of Thermocouple?

RTDs are preferred over thermocouples in applications where high accuracy and stability over a narrow temperature range are essential, such as in laboratory environments, pharmaceutical manufacturing, and precision instrumentation. RTDs also have a longer lifespan and require less frequent recalibration, reducing maintenance costs.

RTD vs. Thermocouple vs. Thermistor: How do they compare?

Each sensor type has its advantages and limitations. Thermistors are semiconductor devices offering high sensitivity and low cost but limited temperature range compared to RTDs and Thermocouples.

What factors should be considered when choosing between RTD and Thermocouple?

Key considerations include:

- Temperature range requirements

- Accuracy and precision

- Response time

- Cost and maintenance considerations

- Environmental conditions (e.g., vibration, electromagnetic interference)

- Integration with existing systems or instrumentation

Related Knowledge Guides:

- What is an RTD Sensor?

- What is a Thermocouple?

- How Accurate are Thermocouples?

- Advantages and Disadvantages of Thermocouples

- What Is A Temperature Sensor?

- Thermistors vs Thermocouples: Choosing the Right Sensor

- Difference Between 2-Wire, 3-Wire, and 4-Wire RTDs

- What is a Temperature Transmitter?

- Pt100 Wiring Methods – 2, 3 or 4 wire?

- What is a Pt100 Sensor Working Principle?

- Pt100 Temperature Sensor Specification