Case Study: Integrating Industrial Thermal Imaging Cameras in Truck Manufacturing

Enhancing Safety in Electric Truck Production for the UK’s Largest Truck Manufacturer

Process Parameters Ltd, a leading supplier of industrial temperature measurement products, recently collaborated with the UK’s largest truck manufacturer to enhance safety in battery-powered truck production.

This case study highlights both the technical and collaborative achievements of integrating industrial thermal imaging cameras into the manufacturer’s production process.

Project Background

As the manufacturer expanded its range of battery-powered vehicles, safely monitoring battery temperatures became a priority. Elevated temperatures in batteries can be an early warning of thermal runaway, which poses serious risks, including fires or explosions. Both the manufacturer and their insurance provider recognised the necessity of installing thermal imaging cameras to detect temperature anomalies early.

Our Solution

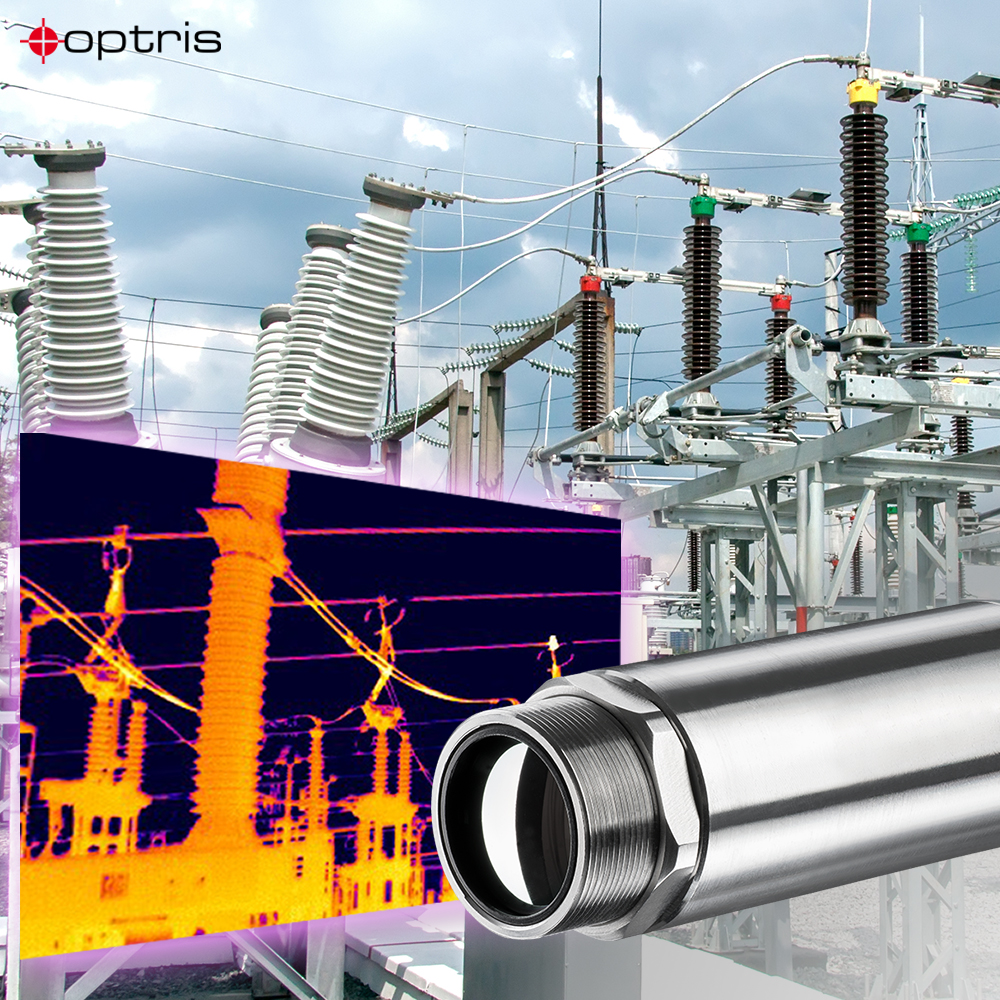

As the UK distributor for Optris GmbH, Process Parameters Ltd was commissioned to supply fixed industrial thermal imaging cameras. These cameras were chosen for their ability to provide real-time monitoring and integrate directly with the factory fire alarm system, ensuring any temperature irregularities would trigger immediate alerts.

Technical Integration

The cameras were installed by the customer, who also maintains the factory’s fire alarm system, with support from our team. Optris Xi410 thermal cameras were selected for their simple Ethernet connectivity, enabling live thermal video feeds to a PC on the shop floor. This setup allows operators to monitor each camera and oversee batteries in real time.

The cameras’ IP65 rating ensures robust performance in factory conditions. For ease of mounting and protection, the cameras were supplied in compact housings, which are especially advantageous for outdoor use as their built-in heaters prevent moisture accumulation.

A critical element of the system is the Industrial Process Interface accessory, which links the cameras to the fire alarm network. It provides a digital output that activates when a set temperature threshold is exceeded, enabling automated alerts and rapid safety responses. Additionally, built-in fail-safe functionality monitors the thermal camera system itself, issuing independent alarms in case of faults, even during power failures.

Key Benefits

- Enhanced Safety: Continuous, real-time battery temperature monitoring enables the detection and resolution of anomalies before they escalate, reducing the risk of thermal runaway.

- Seamless Integration: The cameras interface smoothly with the existing fire alarm infrastructure, minimising operational disruption and demonstrating product adaptability.

- Reliability and Precision: The system provides accurate temperature readings for precise, reliable monitoring – crucial for safe, efficient manufacturing.

Collaborative Approach

The project’s success stemmed from close collaboration between our team and the customer’s technical staff. This open partnership ensured challenges were promptly addressed and the system was effectively implemented, contributing to a smooth installation process.

Client Feedback

The truck manufacturer has reported high satisfaction with both the performance of the thermal imaging cameras and our collaborative support. They have experienced significant improvements in monitoring battery temperatures and mitigating risks. Plans are underway to expand the system into additional battery-handling areas within the factory.

Conclusion

This project demonstrates how industrial thermal imaging cameras can significantly enhance safety in battery-powered truck manufacturing. The seamless integration with existing systems and the collaborative implementation process reflect our commitment to delivering reliable, effective temperature measurement solutions.

Thermal imaging is now widely recognised as a vital technology in the monitoring and management of EV and lithium-based battery systems throughout manufacturing and storage.

This case study serves as a guide, but our free technical assistance is always available for further support.

If you need help selecting a thermal imaging camera, please reach out to us. We’re here to discuss your application and assist you with your product choices.

Email us at sales@processparameters.co.uk, call 01628 778788, or complete our online enquiry form.

Send An EnquiryIndustrial Thermal Imaging Cameras

Industrial Thermal Imaging Cameras

Optris PI400i/PI450i High Resolution Thermal Imaging Cameras

Industrial Thermal Imaging Cameras

Industrial Thermal Imaging Cameras

Related Guides:

- Temperature Sensors for Food Production

- Monitoring Lithium Ion Battery Charging in Automotive Applications

- Use of Infrared Thermal Imaging Camera for Fire Detection in Recycling Centre

- How Can You Improve Efficiency With Infrared Cameras?

- 5 Benefits & Applications of Thermal Imaging Cameras

- Temperature Sensors for Oil and Gas Industries